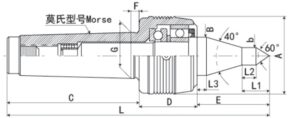

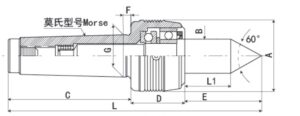

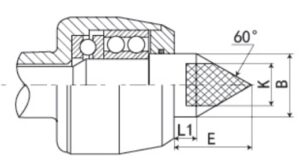

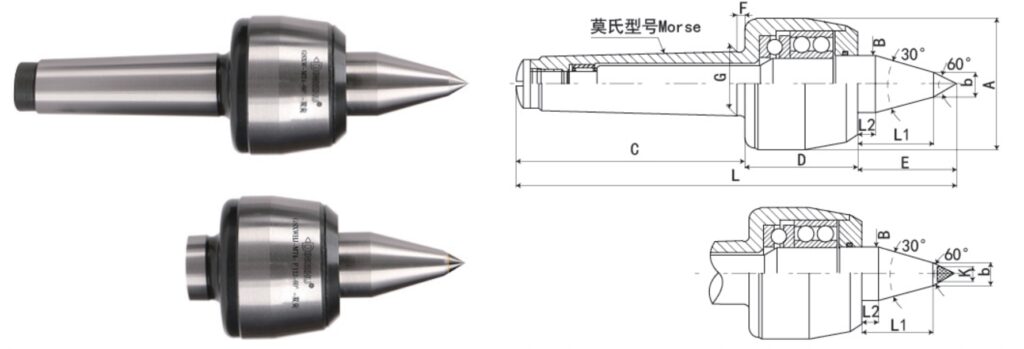

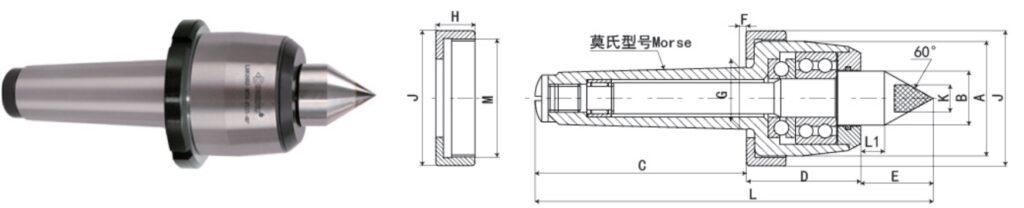

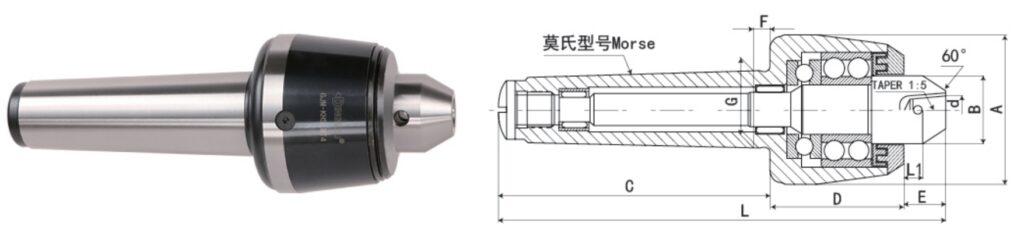

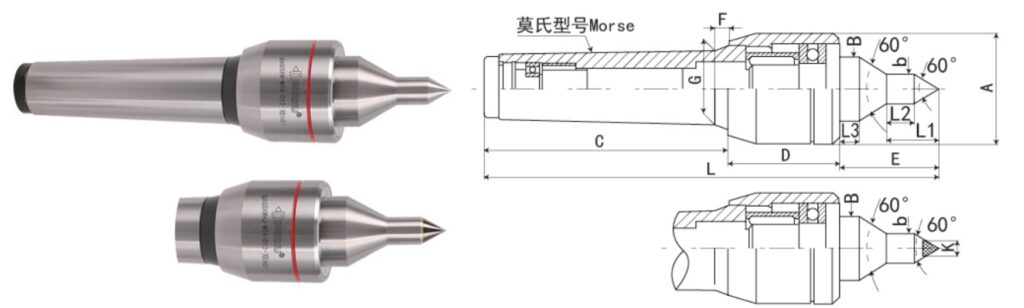

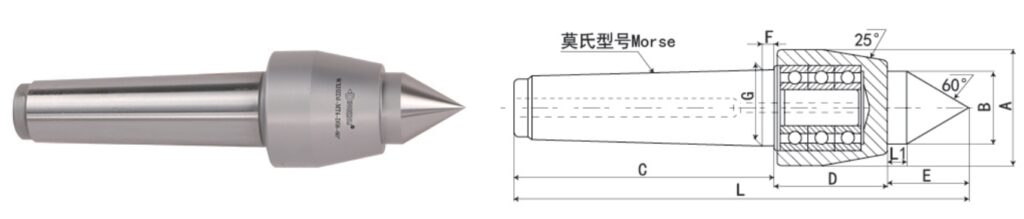

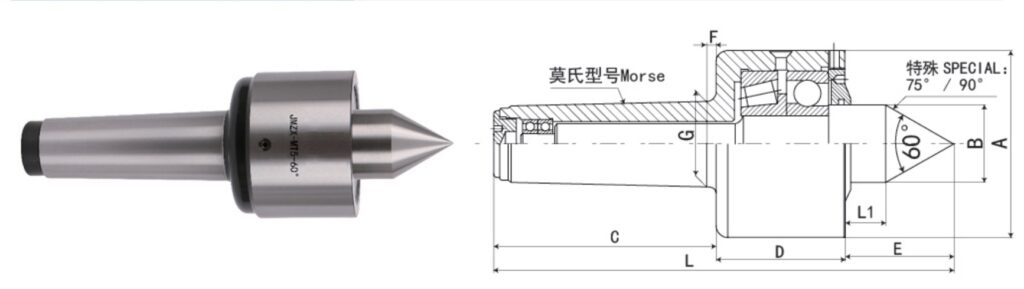

MEDIUM-DUTY LIVE CENTER(OILING TYPE)

-1-300x115.jpg)

-3-300x169.jpg)

-2-300x129.jpg)

-4-300x141.jpg)

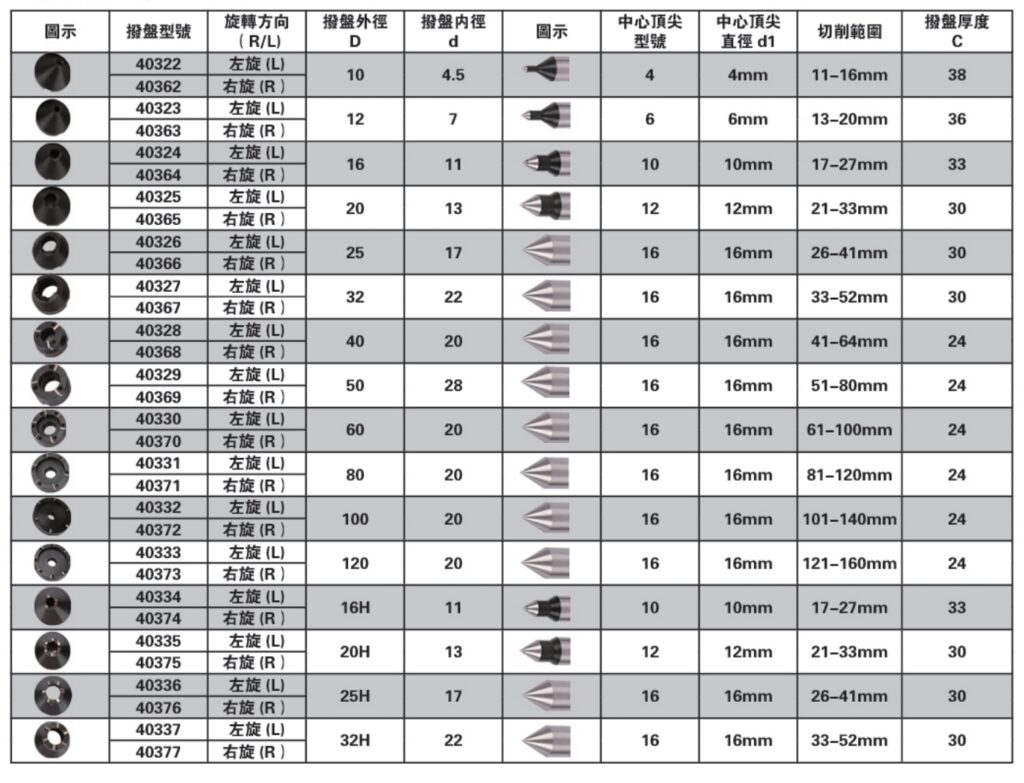

| Morse | Type | L | L1 | A | B | C | D | E | F | G | K |

| MT1 | ZX-MT1-60ᄚ131 | 131 | 9 | 41 | 19 | 57 | 48 | 26 | 5 | 12.065 | / |

| MT1 | ZXHJ-MT1-F108-60ᄚ | 131 | 9 | 41 | 19 | 57 | 48 | 26 | 5 | 12.065 | 8 |

| MT2 | ZX-MT2-60ᄚ | 151 | 10 | 48 | 22 | 69 | 53 | 29 | 5 | 17.780 | / |

| MT2 | ZXHJ-MT2-F108-60ᄚ | 151 | 10 | 48 | 22 | 69 | 53 | 29 | 5 | 17.780 | 8 |

| MT3 | ZX-MT3-60ᄚ | 173 | 12 | 53 | 27 | 86 | 52 | 35 | 5 | 23.825 | / |

| MT3 | ZXHJ-MT3-F112-60ᄚ | 173 | 12 | 53 | 27 | 86 | 52 | 35 | 5 | 23.825 | 12 |

| MT4 | ZX-MT4-60ᄚ | 205 | 18 | 63 | 31 | 109 | 51 | 45 | 6 | 31.267 | / |

| MT4 | ZXHJ-MT4-F115-60ᄚ | 205 | 18 | 63 | 31 | 109 | 51 | 45 | 6 | 31.267 | 15 |

| MT5 | ZX-MT5-60ᄚ | 243 | 20 | 78 | 35 | 136 | 57 | 50 | 6 | 44.399 | / |

| MT5 | ZXHJ-MT5-F118-60ᄚ | 243 | 20 | 78 | 35 | 136 | 57 | 50 | 6 | 44.399 | 18 |

| MT6 | ZX-MT6-60ᄚ | 353 | 25 | 120 | 57 | 190 | 88 | 75 | 8 | 63.348 | / |

| MT6 | ZXHJ-MT6-F124-60ᄚ | 353 | 25 | 120 | 57 | 190 | 88 | 75 | 8 | 63.348 | 24 |

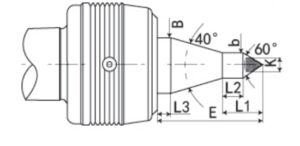

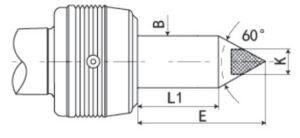

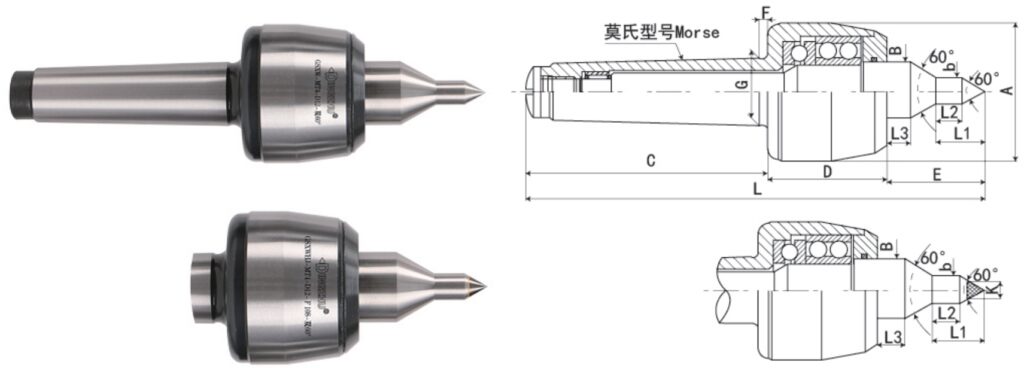

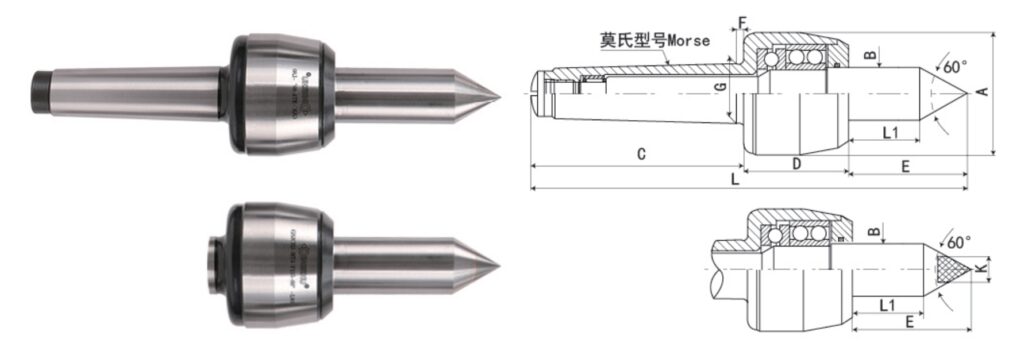

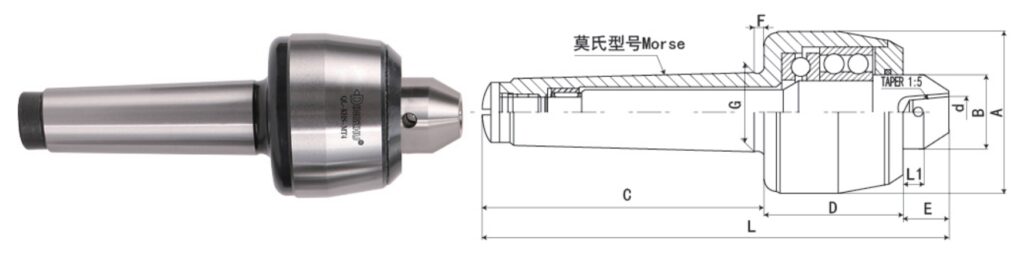

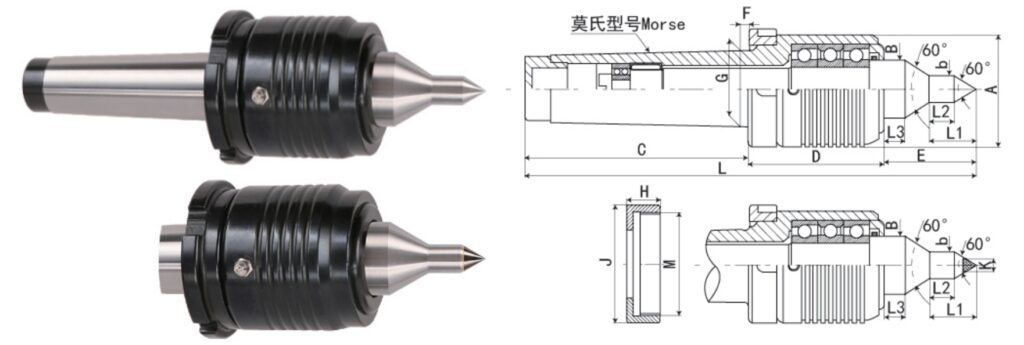

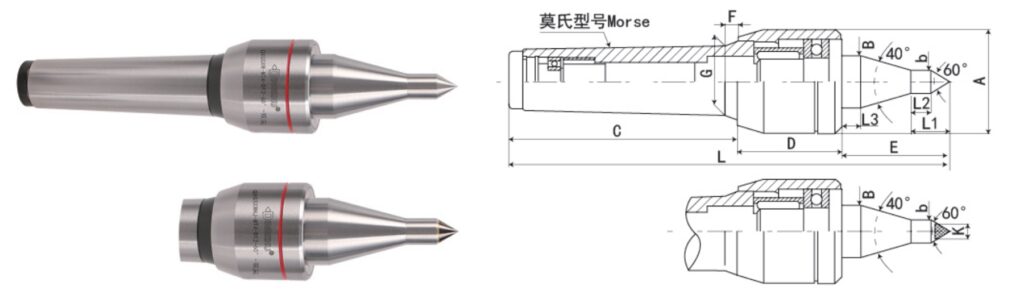

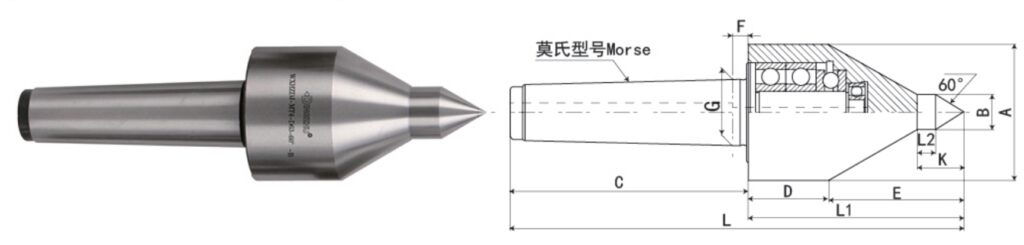

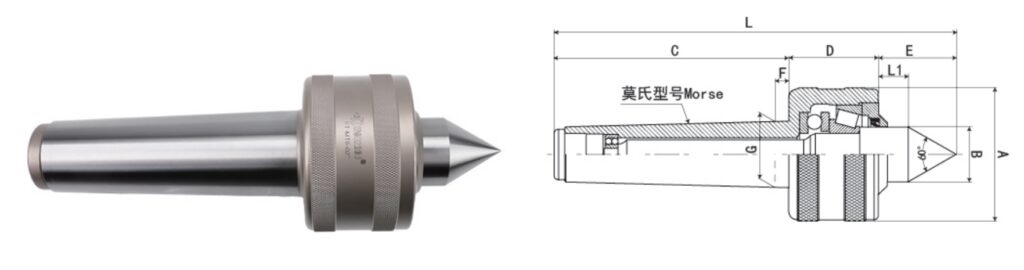

A MEDIUM-DUTY FOR SLIM LIVE CENTER(OILING TYPE)

-1-300x102.jpg)

-3-300x124.jpg)

-2-300x121.jpg)

-4-300x140.jpg)

Features:

Bearing Combination: The center features an advanced combination of deep groove ball bearings and ball thrust bearings, providing optimal support and stability during operation.

Application: It is specifically designed for medium-speed, precision machining of medium-load tasks on CNC lathes, ensuring high accuracy and performance.

Material and Hardness: Crafted from high-quality alloy tool steel, the center undergoes rigorous heat treatment, achieving a hardness level of HRC 55-60. This enhances its durability and wear resistance, making it suitable for demanding applications.

Anti-Dust Seal: Equipped with a front anti-dust seal, the center effectively prevents cutting fluid and dust from penetrating the bearings, significantly extending its service life and maintaining performance over time.

| Morse | Type | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K |

| MT3 | ZXXW-MT3-D10-雙 60° | 186 | 21 | 12 | 12 | 53 | 27 | 10 | 86 | 52 | 47 | 5 | 23.825 | / |

| MT3 | ZXXWHJ-MT3-D12-F108-雙 60° | 186 | 21 | 12 | 12 | 53 | 27 | 10 | 86 | 52 | 47 | 5 | 23.825 | 8 |

| MT4 | ZXXW-MT4-D12-雙 60° | 216 | 24.5 | 14 | 15 | 63 | 31 | 12 | 109 | 51 | 56 | 6 | 31.267 | / |

| MT4 | ZXXWHJ-MT4-D12-F108-雙 60° | 216 | 24.5 | 14 | 15 | 63 | 31 | 12 | 109 | 51 | 56 | 6 | 31.267 | 8 |

| MT5 | ZXXW-MT5-D16-雙 60° | 255 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 57 | 62 | 6 | 44.399 | / |

| MT5 | ZXXWHJ-MT5-D16-F112-雙60° | 255 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 57 | 62 | 6 | 44.399 | 12 |

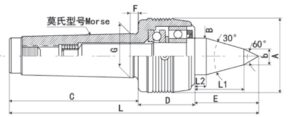

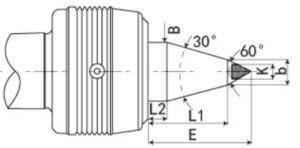

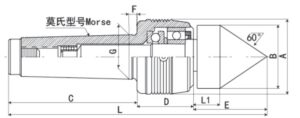

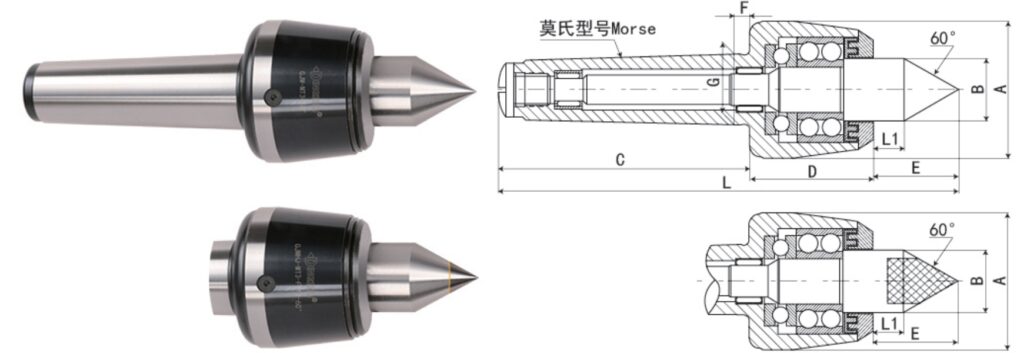

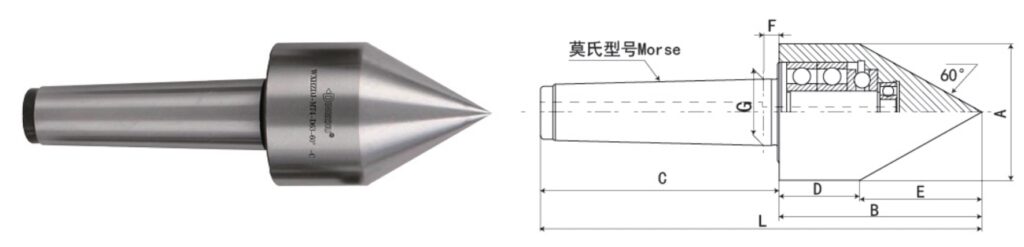

B MEDIUM-DUTY FOR SLIM LIVE CENTER(OILING TYPE)

| Morse | Type | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K |

| MT3 | ZXXW-MT3-D10-60°-雙尖 | 193 | 21 | 12 | 12 | 53 | 27 | 10 | 86 | 52 | 55 | 5 | 23.825 | / |

| MT3 | ZXXWHJ-MT3-D12-F108-60°-雙尖 | 193 | 21 | 12 | 12 | 53 | 27 | 10 | 86 | 52 | 55 | 5 | 23.825 | 8 |

| MT4 | ZXXW-MT4-D12-60°-雙尖 | 225 | 24.5 | 14 | 15 | 63 | 31 | 12 | 109 | 51 | 65 | 6 | 31.267 | / |

| MT4 | ZXXWHJ-MT4-D12-F108-60°-雙尖 | 225 | 24.5 | 14 | 15 | 63 | 31 | 12 | 109 | 51 | 65 | 6 | 31.267 | 8 |

| MT5 | ZXXW-MT5-D16-60°-雙尖 | 265 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 57 | 72 | 6 | 44.399 | / |

| MT5 | ZXXWHJ-MT5-D16-F112-60°-雙尖 | 265 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 57 | 72 | 6 | 44.399 | 12 |

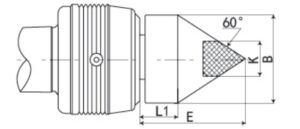

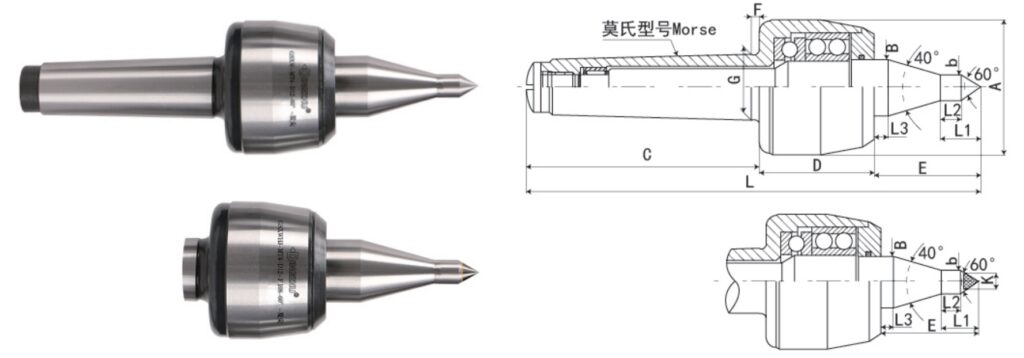

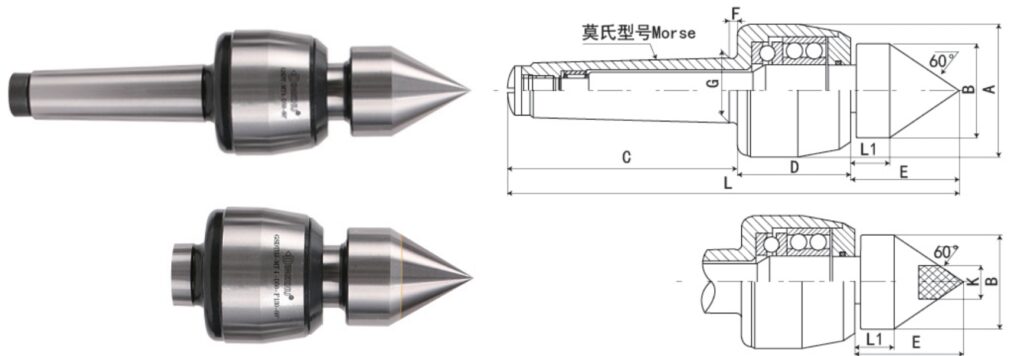

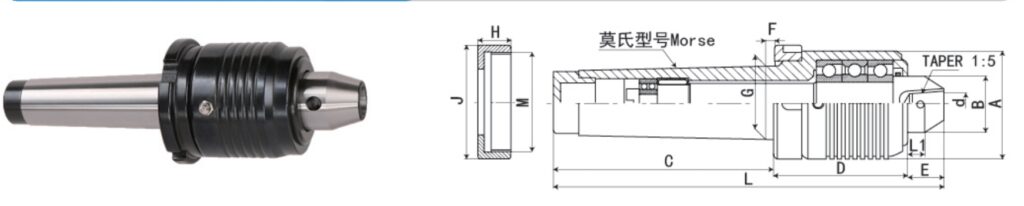

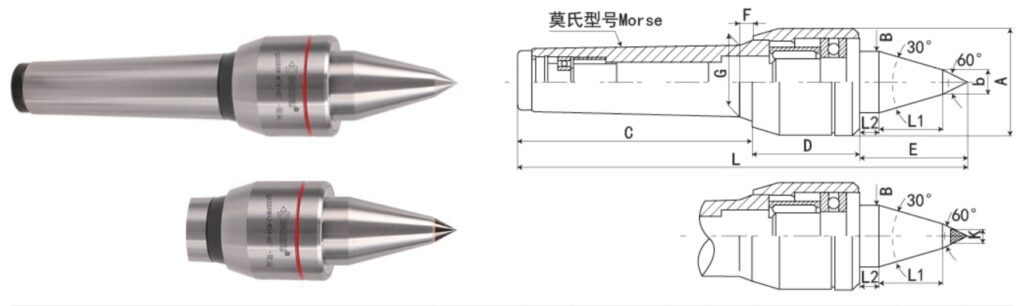

C MEDIUM-DUTY FOR SLIM LIVE CENTER(OILING TYPE)

Features:

Bearing Combination: The center utilizes a sophisticated combination of deep groove ball bearings and ball thrust bearings, optimizing both radial and axial load handling for improved performance and precision.

Application: Designed specifically for medium-speed, precision processing of medium-load applications on CNC lathes, this center ensures reliable and accurate machining.

Material and Durability: Constructed from high-quality alloy tool steel, the center undergoes heat treatment to achieve a hardness level of HRC 55°-60°. This enhances its strength and wear resistance, ensuring long-term durability even under demanding conditions.

Dust Protection: Equipped with an anti-dust seal at the front, the center effectively prevents cutting fluid and dust from contaminating the bearings. This feature significantly extends the service life of the bearings, reducing maintenance needs and enhancing overall machine reliability.

| Morse | Type | L | L1 | L2 | A | B | b | C | D | E | F | G | K |

| MT3 | ZXXW-MT3-60°-雙尖 | 189 | 42 | 12 | 53 | 27 | 12 | 86 | 52 | 51 | 5 | 23.825 | / |

| MT3 | ZXXWHJ-MT3-F108-60°-雙尖 | 189 | 42 | 12 | 53 | 27 | 12 | 86 | 52 | 51 | 5 | 23.825 | 8 |

| MT4 | ZXXW-MT4-60°-雙尖 | 221 | 51 | 15 | 63 | 31 | 12 | 109 | 51 | 61 | 6 | 31.267 | / |

| MT4 | ZXXWHJ-MT4-F108-60°-雙尖 | 221 | 51 | 15 | 63 | 31 | 12 | 109 | 51 | 61 | 6 | 31.267 | 8 |

| MT5 | ZXXW-MT5-60°-雙尖 | 258 | 51 | 16 | 78 | 35 | 16 | 136 | 57 | 65 | 6 | 44.399 | / |

| MT5 | ZXXWHJ-MT5-F112-60°-雙尖 | 258 | 51 | 16 | 78 | 35 | 16 | 136 | 57 | 65 | 6 | 44.399 | 12 |

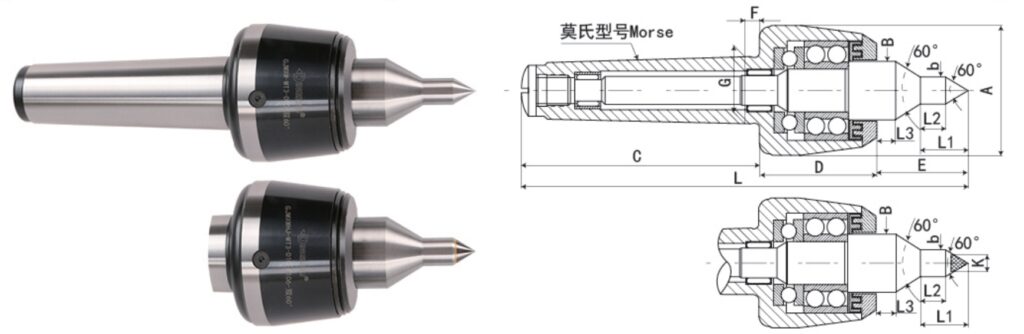

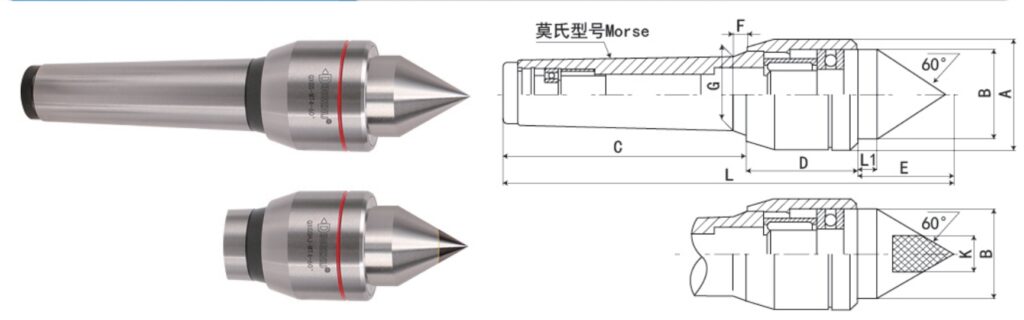

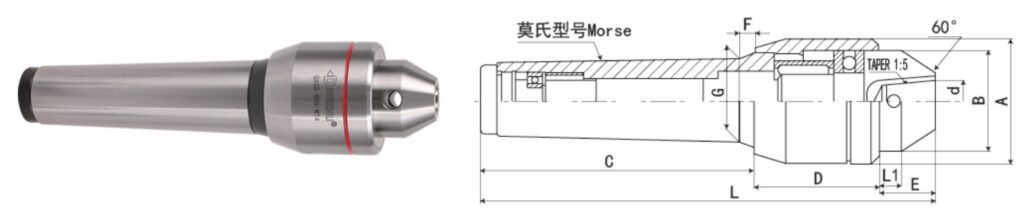

MEDIUM-DUTY EXTENSION LIVE CENTER(OILING TYPE)

| Morse | Type | L | L1 | A | B | C | D | E | F | G | K |

| MT3 | ZXJC-MT3-60ᄚ-L70 | 208 | 47 | 53 | 27 | 86 | 52 | 70 | 5 | 23.825 | / |

| MT3 | ZXJCHJ-MT3-F112-60ᄚ-L70 | 208 | 47 | 53 | 27 | 86 | 52 | 70 | 5 | 23.825 | 12 |

| MT4 | ZXJC-MT4-60ᄚ-L80 | 240 | 53 | 63 | 31 | 109 | 51 | 80 | 6 | 31.267 | / |

| MT4 | ZXJCHJ-MT4-F115-60ᄚ-L80 | 240 | 53 | 63 | 31 | 109 | 51 | 80 | 6 | 31.267 | 15 |

| MT5 | ZXJC-MT5-60ᄚ-L100 | 293 | 70 | 78 | 35 | 136 | 57 | 100 | 6 | 44.399 | / |

| MT5 | ZXJCHJ-MT5-F118-60ᄚ-L100 | 293 | 70 | 78 | 35 | 136 | 57 | 100 | 6 | 44.399 | 18 |

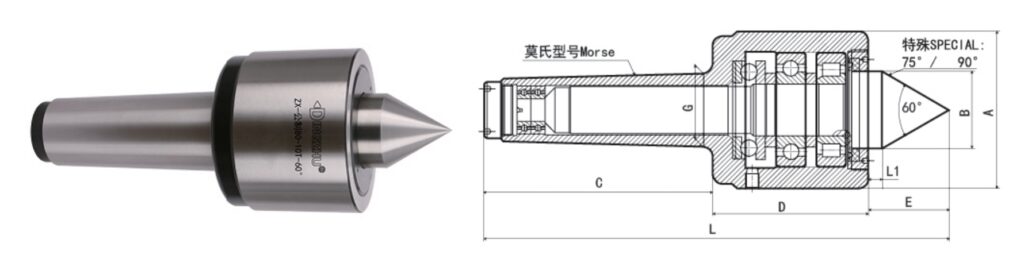

MEDIUM-DUTY OVERSIZED LIVE CENTER(OILING TYPE)

Features:

Bearing Configuration: This center employs a dual bearing system, combining deep groove ball bearings with ball thrust bearings. This configuration enhances both radial and axial load capabilities, offering superior precision and reliability.

Versatile Application: Ideal for medium-speed, precise machining of medium-load components on CNC lathes, ensuring consistent performance and accuracy.

Robust Construction: Crafted from high-grade alloy tool steel, the center is heat-treated to achieve a hardness of HRC 55°-60°. This provides exceptional durability and resistance to wear, making it suitable for demanding machining tasks.

Enhanced Longevity: Featuring a front anti-dust seal, the center effectively prevents the ingress of cutting fluids and dust into the bearings. This protective measure extends the service life of the bearings and reduces maintenance requirements, ensuring long-term operational efficiency.

| Morse | Type | L | L1 | A | B | C | D | E | F | G | K |

| MT3 | ZXDT-MT3-D49-60° | 203 | 22 | 53 | 49 | 86 | 52 | 65 | 5 | 23.825 | / |

| MT3 | ZXDTHJ-MT3-D49-F130-60° | 203 | 22 | 53 | 49 | 86 | 52 | 65 | 5 | 23.825 | 30 |

| MT4 | ZXDT-MT4-D49-60° | 225 | 22 | 63 | 49 | 109 | 51 | 65 | 6 | 31.267 | / |

| MT4 | ZXDTHJ-MT4-D49-F130-60° | 225 | 22 | 63 | 49 | 109 | 51 | 65 | 6 | 31.267 | 30 |

| MT5 | ZXDT-MT5-D59-60° | 266 | 22 | 78 | 59 | 136 | 57 | 73 | 6 | 44.399 | / |

| MT5 | ZXDTHJ-MT5-D59-F136-60° | 266 | 22 | 78 | 59 | 136 | 57 | 73 | 6 | 44.399 | 36 |

HIGH-SPEED LIVE CENTER

| Morse | Type | L | L1 | A | B | C | D | E | F | G | K |

| MT3 | GS-MT3-60° | 170 | 18 | 48 | 26 | 86 | 45 | 39 | 5 | 23.825 | / |

| MT3 | GSHJ-MT3-F112-60° | 170 | 18 | 48 | 26 | 86 | 45 | 39 | 5 | 23.825 | 12 |

| MT4 | GS-MT4-60° | 204 | 18 | 68 | 31 | 109 | 50 | 45 | 6 | 31.267 | / |

| MT4 | GSHJ-MT4-F115-60° | 204 | 18 | 68 | 31 | 109 | 50 | 45 | 6 | 31.267 | 15 |

| MT5 | GS-MT5-60° | 251 | 20 | 78 | 35 | 136 | 65 | 50 | 6 | 44.399 | / |

| MT5 | GSHJ-MT5-F118-60° | 251 | 20 | 78 | 35 | 136 | 65 | 50 | 6 | 44.399 | 18 |

A HIGH-SPEED FOR SLIM LIVE CENTER

Features:

Advanced Bearing Configuration: This center features a sophisticated combination of double row angular contact ball bearings, thrust ball bearings, and needle roller bearings. This multi-bearing setup provides excellent support for both radial and axial loads, ensuring enhanced precision and stability.

Precision and Speed: Designed for medium to high-speed, precise machining of medium-load components on CNC lathes, the center delivers exceptional performance and accuracy in demanding applications.

Enhanced Cutting Performance: The extended mandrel design significantly improves cutting performance by reducing vibration. This results in smoother operation and higher-quality finishes.

Durable Construction: Made from premium alloy tool steel, the center undergoes heat treatment to achieve a hardness of HRC 60° ± 2°. This treatment ensures high steel performance and exceptional wear resistance, even under rigorous conditions.

Effective Dust Protection: The front anti-dust seal effectively prevents cutting fluids and dust from entering the bearings. This protective feature extends the service life of the bearings and minimizes maintenance, contributing to long-term reliability and efficiency.

| Morse | Type | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K |

| MT3 | GSXW-MT3-D10-雙60° | 181 | 21 | 12 | 15 | 48 | 26 | 10 | 86 | 45 | 50 | 5 | 23.825 | / |

| MT3 | GSXWHJ-MT3-D12-F106-雙60° | 181 | 21 | 12 | 15 | 48 | 26 | 12 | 86 | 45 | 50 | 5 | 23.825 | 6 |

| MT4 | GSXW_MT4-D12-雙60° | 215 | 24.5 | 14 | 15 | 68 | 31 | 12 | 109 | 50 | 56 | 6 | 31.267 | / |

| MT4 | GSXWHJ-MT4-D12-F108-雙 60° | 215 | 24.5 | 14 | 15 | 68 | 31 | 12 | 109 | 50 | 56 | 6 | 31.267 | 8 |

| MT5 | GSXW-MT5-D16-雙 60° | 263 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 65 | 62 | 6 | 44.399 | / |

| MT5 | GSXWHJ-MT5-D16-F112-雙60° | 263 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 65 | 62 | 6 | 44.399 | 12 |

B HIGH-SPEED FOR SLIM LIVE CENTER

| Morse | Type | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K |

| MT3 | GSXW-MT3-D10-60°-雙尖 | 186 | 21 | 12 | 15 | 48 | 26 | 10 | 86 | 45 | 55 | 5 | 23.825 | / |

| MT3 | GSXWHJ-MT3-D12-F106-60°-雙尖 | 186 | 21 | 12 | 15 | 48 | 26 | 12 | 86 | 45 | 55 | 5 | 23.825 | 6 |

| MT4 | GSXW_MT4-D12-60°-雙尖 | 225 | 24.5 | 14 | 15 | 68 | 31 | 12 | 109 | 50 | 66 | 6 | 31.267 | / |

| MT4 | GSXWHJ-MT4-D12-F108-60°-雙尖 | 225 | 24.5 | 14 | 15 | 68 | 31 | 12 | 109 | 50 | 66 | 6 | 31.267 | 8 |

| MT5 | GSXW-MT5-D16-60°-雙尖 | 273 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 65 | 72 | 6 | 44.399 | / |

| MT5 | GSXWHJ-MT5-D16-F112-60°-雙尖 | 273 | 30 | 16 | 16 | 78 | 35 | 16 | 136 | 65 | 72 | 6 | 44.399 | 12 |

C HIGH-SPEED FOR SLIM LIVE CENTER

Features:

The center features a robust design combining double-row angular contact ball bearings, thrust ball bearings, and needle roller bearings, ensuring superior stability and performance.

Specifically designed for medium to high-speed precision machining on CNC lathes, it is ideal for handling medium-load applications.

The extended mandrel is engineered to significantly improve cutting performance while minimizing vibration, resulting in smoother operations.

Constructed from high-quality alloy tool steel, the center undergoes rigorous heat treatment, achieving a hardness level of HRC 60° ± 2°, which provides excellent strength and high wear resistance.

Equipped with a front anti-dust seal, the center effectively prevents cutting fluids and debris from entering the bearings, thereby enhancing durability and extending the service life of the product.

| Morse | Type | L | L1 | L2 | A | B | b | C | D | E | F | G | K |

| MT3 | GSXW-MT3-60°-雙尖 | 185 | 46 | 15 | 48 | 26 | 10 | 86 | 45 | 54 | 5 | 23.825 | / |

| MT3 | GSXWHJ-MT3-F106-60°-雙尖 | 185 | 46 | 15 | 48 | 26 | 10 | 86 | 45 | 54 | 5 | 23.825 | 6 |

| MT4 | GSXW-MT4-60°-雙尖 | 220 | 51 | 15 | 68 | 31 | 12 | 109 | 50 | 61 | 6 | 31.267 | / |

| MT4 | GSXWHJ-MT4-F108-60°-雙尖 | 220 | 51 | 15 | 68 | 31 | 12 | 109 | 50 | 61 | 6 | 31.267 | 8 |

| MT5 | GSXW-MT5-60°-雙尖 | 266 | 51 | 16 | 78 | 35 | 16 | 136 | 65 | 65 | 6 | 44.399 | / |

| MT5 | GSXWHJ-MT5-F112-60°-雙尖 | 266 | 51 | 16 | 78 | 35 | 16 | 136 | 65 | 65 | 6 | 44.399 | 12 |

HIGH-SPEED EXTENSION LIVE CENTER

| Morse | Type | L | L1 | A | B | C | D | E | F | G | K |

| MT3 | GSJC-MT3-60ᄚ-L70 | 201 | 47 | 48 | 26 | 86 | 45 | 70 | 5 | 23.825 | / |

| MT3 | GSJCHJ-MT3-F112-60ᄚ-L70 | 201 | 47 | 48 | 26 | 86 | 45 | 70 | 5 | 23.825 | 12 |

| MT4 | GSJC-MT4-60ᄚ-L80 | 239 | 53 | 68 | 31 | 109 | 50 | 80 | 6 | 31.267 | / |

| MT4 | GSJCHJ-MT4-F115-60ᄚ-L80 | 239 | 53 | 68 | 31 | 109 | 50 | 80 | 6 | 31.267 | 15 |

| MT5 | GSJC-MT5-60ᄚ-L100 | 301 | 70 | 78 | 35 | 136 | 65 | 100 | 6 | 44.399 | / |

| MT5 | GSJCHJ-MT5-F118-60ᄚ-L100 | 301 | 70 | 78 | 35 | 136 | 65 | 100 | 6 | 44.399 | 18 |

HIGH-SPEED OVERSIZED LIVE CENTER

Features:

The center integrates a combination of double-row angular contact ball bearings, thrust ball bearings, and needle roller bearings, delivering exceptional stability, precision, and load-bearing capacity.

It is designed for medium to high-speed precision machining, making it highly suitable for medium-load applications in CNC lathes, where consistent performance and accuracy are critical.

The extended mandrel enhances cutting performance by reducing vibration and ensuring smoother operation, which contributes to superior machining quality and efficiency.

Crafted from high-grade alloy tool steel, the center undergoes heat treatment to achieve a hardness of HRC 60ᄚ ᄆ 2ᄚ, offering excellent mechanical properties, including high strength, durability, and wear resistance.

A front anti-dust seal effectively protects the internal bearings from cutting fluids and contaminants, thereby extending the service life of the center and maintaining optimal performance over time.

| Morse | Type | L | L1 | A | B | C | D | E | F | G | K |

| MT3 | GSDT-MT3-D49-60ᄚ | 199 | 26 | 48 | 49 | 86 | 45 | 68 | 5 | 23.825 | / |

| MT3 | GSDTHJ-MT3-D49-F130-60ᄚ | 199 | 26 | 48 | 49 | 86 | 45 | 68 | 5 | 23.825 | 30 |

| MT4 | GSDT-MT4-D49-60ᄚ | 227 | 26 | 68 | 49 | 109 | 50 | 68 | 6 | 31.267 | / |

| MT4 | GSDTHJ-MT4-D49-F130-60ᄚ | 227 | 26 | 68 | 49 | 109 | 50 | 68 | 6 | 31.267 | 30 |

| MT5 | GSDT-MT5-D59-60ᄚ | 281 | 29 | 78 | 59 | 136 | 65 | 80 | 6 | 44.399 | / |

| MT5 | GSDTHJ-MT5-D59-F136-60ᄚ | 281 | 29 | 78 | 59 | 136 | 65 | 80 | 6 | 44.399 | 36 |

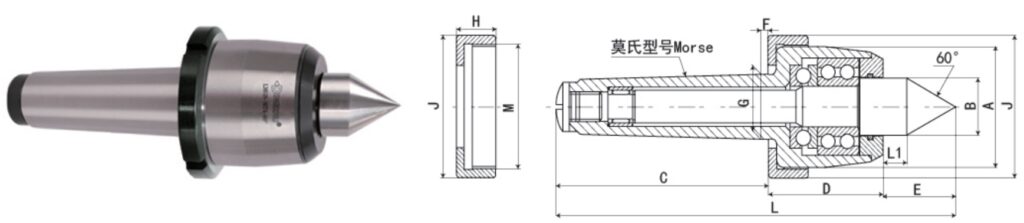

A HIGH-SPEED LIVE CENTER WITH REMOVABLE NUT

| Morse | Model | L | L1 | A | B | C | D | E | F | G | H | M | J |

| MT3 | LMGS-MT3-60° | 170 | 18 | 48 | 26 | 86 | 45 | 39 | 5 | 23.825 | 15 | M60*1.5P | 58 |

| MT4 | LMGS-MT4-60° | 204 | 18 | 68 | 31 | 109 | 50 | 45 | 6.5 | 31.267 | 20 | M60*2.0P | 78 |

| MT5 | LMGS-MT5-60° | 251 | 20 | 78 | 35 | 136 | 65 | 50 | 6.5 | 44.399 | 20 | M60*2.0P | 88 |

B HIGH-SPEED LIVE CENTER WITH REMOVABLE NUT

Features:

The center is engineered with a combination of double-row deep groove ball bearings, thrust ball bearings, and needle roller bearings, providing exceptional stability, precision, and support for a wide range of machining applications.

The extended mandrel is designed to effectively improve cutting performance by reducing vibration, resulting in smoother and more precise machining.

Constructed from high-quality alloy tool steel, the center undergoes heat treatment to achieve a hardness of HRC 60° ± 2°, offering superior strength, enhanced steel performance, and excellent wear resistance.

The main body features a removable nut that can be easily pressed out from the front, allowing for simple use and disassembly in various situations, enhancing operational convenience.

Equipped with a front anti-dust seal, the center effectively prevents cutting fluids and dust from entering the bearings, thereby prolonging its service life and maintaining optimal performance.

| Morse | Model | L | L1 | A | B | C | D | E | F | G | K | H | M | J |

| MT3 | LMGSHJ-MT3-F112-60° | 170 | 18 | 48 | 26 | 86 | 45 | 39 | 5 | 23.825 | 12 | 15 | M60*1.5P | 58 |

| MT4 | LMGSHJ-MT4-F115-60° | 204 | 18 | 68 | 31 | 109 | 50 | 45 | 6.5 | 31.267 | 15 | 20 | M60*2.0P | 78 |

| MT5 | LMGSHJ-MT5-F118-60° | 251 | 20 | 78 | 35 | 136 | 65 | 50 | 6.5 | 44.399 | 18 | 20 | M68*2.0P | 88 |

HIGH-SPEED LIVE CENTER(CANCHANGE)

| Morse | Model | L | L1 | A | B | d | C | D | E | F | G |

| MT3 | GS-KHS-MT3 | 159 | 15 | 48 | 30 | 12.5 | 86 | 45 | 28 | 5 | 23.825 |

| MT4 | GS-KHS-MT4 | 187 | 15 | 68 | 32 | 12.5/15.5 | 109 | 50 | 28 | 6.5 | 31.267 |

| MT5 | GS-KHS-MT5 | 233 | 16 | 78 | 40 | 15.5 | 136 | 65 | 32 | 6.5 | 44.399 |

HIGH-PRECISION MEDIUM LIVE CENTER

| Morse | Model | L | L1 | A | B | C | D | E | F | G |

| MT3 | GJM-MT3-60° | 181 | 14 | 53 | 30 | 86 | 40 | 5 | 23.825 | / |

| MT3 | GJMHJ-MT3-F112-60° | 181 | 14 | 53 | 30 | 86 | 40 | 5 | 23.825 | 12 |

| MT4 | GJM-MT4-60° | 213 | 17 | 68 | 32 | 109 | 47 | 6 | 31.267 | / |

| MT4 | GJMHJ-MT4-F115-60° | 213 | 17 | 68 | 32 | 109 | 47 | 6 | 31.267 | 15 |

| MT5 | GJM-MT5-60° | 260 | 18 | 83 | 40 | 136 | 53 | 6 | 44.399 | / |

| MT5 | GJMHJ-MT5-F118-60° | 260 | 18 | 83 | 40 | 136 | 53 | 6 | 44.399 | 18 |

| MT6 | GJM-MT6-60° | 398 | 21 | 128 | 68 | 190 | 80 | 8 | 63.348 | / |

| MT6 | GJMHJ-MT6-F124-60° | 398 | 21 | 128 | 68 | 190 | 80 | 8 | 63.348 | 24 |

A HIGH-PRECISION MEDIUM FOR SLIM LIVE CENTER

Features:

The center utilizes a combination of angular contact ball bearings, thrust ball bearings, and two-piece needle roller bearings. It is suitable for medium-load precision processing at high speeds on CNC lathes and can replace the fixed center in grinder finishing applications.

The mandrel extends to the tip of the cone, which enhances cutting performance and minimizes vibration.

Made from alloy steel, the center undergoes heat treatment to achieve a hardness of HRC 60 ± 2, providing high structural integrity and excellent wear resistance.

An oil-adding hole at the head allows lubrication of the internal bearings, effectively extending the service life of the center.

It features a mechanical non-contact seal, offering superior sealing performance.

| Morse | Type | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K |

| MT3 | GJMXW-MT3-D10-雙 60° | 193 | 21 | 12 | 14 | 53 | 30 | 10 | 86 | 55 | 52 | 5 | 23.825 | / |

| MT3 | GJMXWHJ-MT3-D10-F106-雙60° | 193 | 21 | 12 | 14 | 53 | 30 | 10 | 86 | 55 | 52 | 5 | 23.825 | 6 |

| MT4 | GJMXW-MT4-D12-雙 60° | 224 | 24.5 | 14 | 17 | 68 | 32 | 12 | 109 | 57 | 58 | 6 | 31.267 | / |

| MT4 | GJMXWHJ-MT4-D12-F108-雙60° | 224 | 24.5 | 14 | 17 | 68 | 32 | 12 | 109 | 57 | 58 | 6 | 31.267 | 8 |

| MT5 | GJMXW-MT5-D16-雙 60° | 280 | 30 | 16 | 18 | 83 | 40 | 16 | 136 | 72 | 72 | 6 | 44.399 | / |

| MT5 | GJMXWHJ-MT5-D16-F112-雙60° | 280 | 30 | 16 | 18 | 83 | 40 | 16 | 136 | 72 | 72 | 6 | 44.399 | 12 |

HIGH-PRECISION MEDIUM LIVE CENTER(CANCHANGE)

Features:

The center combines double-row angular contact ball bearings, thrust ball bearings, and needle roller bearings, offering enhanced performance.

It is suitable for medium-load, medium-high-speed precision processing on CNC lathes.

The extended mandrel effectively improves cutting performance and reduces vibration.

Constructed from alloy tool steel, the center achieves a hardness of HRC 60 ± 2 after heat treatment, providing excellent strength and wear resistance.

The front anti-dust seal prevents cutting fluid and dust from entering the bearings, thereby extending the service life of the center.

| Morse | Model | L | L1 | A | B | d | C | D | E | F | G |

| MT3 | GJM-KHS-MT3 | 169 | 15 | 53 | 30 | 12.5 | 86 | 55 | 28 | 5 | 23.825 |

| MT4 | GJM-KHS-MT4 | 199 | 15 | 68 | 32 | 12.5/15.5 | 109 | 62 | 28 | 6.5 | 31.267 |

| MT5 | GJM-KHS-MT5 | 239 | 16 | 83 | 40 | 15.5 | 136 | 71 | 32 | 6.5 | 44.399 |

ULTRA PRECISION MEDIUM LIVE CENTER

| Morse | Model | L | L1 | A | B | C | D | E | F | G | K | H | M | J |

| MT3 | CJM-MT3-60° | 203 | 15 | 68 | 31.6 | 86 | 75 | 42 | 5 | 23.825 | / | 20 | M60*2.0P | 78 |

| MT3 | CJMHJ-MT3-F112-60° | 203 | 15 | 68 | 31.6 | 86 | 75 | 42 | 5 | 23.825 | 12 | 20 | M60*2.0P | 78 |

| MT4 | CJM-MT4-60° | 226 | 15 | 68 | 31.6 | 109 | 75 | 42 | 6 | 31.267 | / | 13 | M60*2.0P | 78 |

| MT4 | CJMHJ-MT4-F115-60° | 226 | 15 | 68 | 31.6 | 109 | 75 | 42 | 6 | 31.267 | 15 | 13 | M60*2.0P | 78 |

| MT5 | CJM-MT5-60° | 279 | 19 | 78 | 35 | 136 | 91 | 50 | 6 | 44.399 | / | 16 | M60*1.5P | 95 |

| MT5 | CJMHJ-MT5-F118-60° | 279 | 19 | 78 | 35 | 136 | 91 | 50 | 6 | 44.399 | 18 | 16 | M60*1.5P | 95 |

A ULTRA PRECISION MEDIUM FOR SLIM LIVE CENTER

Features:

The center combines double-row angular contact ball bearings, thrust ball bearings, and two-piece needle roller bearings, enhancing performance and durability.

It is suitable for medium-load, medium-high-speed precision processing on CNC lathes.

The extended mandrel improves cutting performance and reduces vibration effectively.

Made from alloy tool steel, the center achieves a hardness of HRC 60 ± 2 after heat treatment, offering high strength and excellent wear resistance.

The front anti-dust seal prevents cutting fluid and dust from entering the bearings, prolonging the service life.

The main body is equipped with a removable nut that can be pressed out from the front, allowing for easy use and disassembly in various situations.

| Morse | Model | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K | H | M | J |

| MT3 | CJMXW-MT3-D10-雙60° | 211 | 21 | 12 | 15 | 68 | 31.6 | 10 | 86 | 75 | 50 | 5 | 23.825 | / | 20 | M60*2.0P | 78 |

| MT3 | CJMXWHJ-MT3-D10-F106-雙60° | 211 | 21 | 12 | 15 | 68 | 31.6 | 10 | 86 | 75 | 50 | 5 | 23.825 | 6 | 20 | M60*2.0P | 78 |

| MT4 | CJMXW-MT4-D12-雙 60° | 240 | 24.5 | 14 | 15 | 68 | 31.6 | 12 | 109 | 75 | 56 | 6 | 31.267 | / | 20 | M60*2.0P | 78 |

| MT4 | CJMXWHJ-MT4-D12-F108-雙60° | 240 | 24.5 | 14 | 15 | 68 | 31.6 | 12 | 109 | 75 | 56 | 6 | 31.267 | 8 | 20 | M60*2.0P | 78 |

| MT5 | CJMXW-MT5-D16-雙 60° | 273 | 30 | 16 | 16 | 68 | 31.6 | 16 | 136 | 75 | 62 | 6 | 44.399 | / | 20 | M60*2.0P | 78 |

| MT5 | CJMXWHJ-MT5-D16-F112-雙 60° | 273 | 30 | 16 | 16 | 68 | 31.6 | 16 | 136 | 75 | 62 | 6 | 44.399 | 12 | 20 | M60*2.0P | 78 |

ULTRA PRECISION MEDIUM LIVE CENTER(CAN CHANGE)

Features:

The center combines double-row angular contact ball bearings, thrust ball bearings, and two-piece needle roller bearings, enhancing stability and performance.

It is suitable for medium-load, medium-high-speed precision processing on CNC lathes.

The extended mandrel effectively enhances cutting performance and reduces vibration.

Constructed from alloy tool steel, the center is heat-treated to achieve a hardness of HRC 60 ± 2, providing high strength and excellent wear resistance.

The front anti-dust seal prevents cutting fluid and dust from entering the bearings, thus prolonging the service life of the center.

The main body features a removable nut that can be pressed out from the front, enabling easy use and disassembly in various situations.

| Morse | Model | L | L1 | A | B | d | C | D | E | F | G | H | M | J |

| MT3 | CJM-KHS-MT3 | 193 | 15 | 68 | 31.6 | 12.5 | 86 | 75 | 32 | 5 | 23.825 | 20 | M60*2.0P | 78 |

| MT4 | CJM-KHS-MT4 | 216 | 15 | 68 | 31.6 | 12.5/15.5 | 109 | 75 | 32 | 6 | 31.267 | 20 | M60*2.0P | 78 |

| MT5 | CJM-KHS-MT5 | 243 | 15 | 68 | 31.6 | 15.5 | 136 | 75 | 32 | 6 | 44.399 | 20 | M60*2.0P | 78 |

LIGHT HIGH-SPEED LIVE CENTER

| Morse | Model | L | L1 | A | B | C | D | E | F | G | K |

| MT2 | QXGS-MT2-60° | 132 | 8 | 32 | 23 | 69 | 35 | 28 | 5 | 17.78 | / |

| MT2 | OXGSHJ-MT2-F108-60° | 132 | 8 | 2 | 23 | 69 | 35 | 28 | 5 | 17.78 | 8 |

| MT3 | QXGS-MT3-60° | 166 | 7 | 41 | 35 | 86 | 44 | 36 | 5 | 23.825 | / |

| MT3 | QXGSHJ-MT3-F112-60° | 166 | 7 | 41 | 35 | 86 | 44 | 36 | 5 | 23.825 | 12 |

| MT4 | QXGS-MT4-60° | 201 | 7 | 47 | 40 | 109 | 51 | 41 | 6.5 | 31.267 | / |

| MT4 | QXGSHJ-MT4-F115-60° | 201 | 7 | 47 | 40 | 109 | 51 | 41 | 6.5 | 31.267 | 15 |

| MT5 | QXGS-MT5-60° | 262 | 9 | 65 | 52 | 136 | 72 | 54 | 6.5 | 44.399 | / |

| MT5 | QXGSHJ-MT5-F118-60° | 262 | 9 | 65 | 52 | 136 | 72 | 54 | 6.5 | 44.399 | 18 |

A LIGHT HIGH-SPEED FOR SLIM LIVE CENTER

Features:

The center integrates needle roller bearings, thrust ball bearings, and a miniature deep groove ball bearing, offering a robust combination for enhanced performance.

It is suitable for medium-load, medium-high-speed precision processing on CNC lathes.

The extended mandrel improves cutting performance and reduces vibration effectively.

Made from alloy steel, the center is heat-treated to reach a hardness of HRC 60 ± 2, providing high strength and excellent wear resistance.

The anti-dust cover at the front rotates synchronously with the mandrel and forms a mechanical seal with the main body, effectively resisting water and iron chips.

Featuring needle roller bearings, the center has a compact head design, making it suitable for a wide range of applications and capable of bearing large loads.

| Morse | Model | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K |

| MT3 | QXGSXW-MT3-D10-雙 60° | 180 | 21 | 12 | 15 | 41 | 27 | 10 | 86 | 44 | 50 | 5 | 23.825 | / |

| MT3 | QXGSXWHJ-MT3-D10-F106-雙60° | 180 | 21 | 12 | 15 | 41 | 27 | 10 | 86 | 44 | 50 | 5 | 23.825 | 6 |

| MT4 | QXGSXW-MT4-D12-雙 60° | 216 | 24.5 | 14 | 15 | 47 | 31 | 12 | 109 | 51 | 56 | 6.5 | 31.267 | / |

| MT4 | QXGSXWHJ-MT4-D12-F108-雙 60° | 216 | 24.5 | 14 | 15 | 47 | 31 | 12 | 109 | 51 | 56 | 6.5 | 31.267 | 8 |

| MT5 | QXGSXW-MT5-D16-雙 60° | 270 | 30 | 16 | 16 | 65 | 35 | 16 | 136 | 72 | 62 | 6.5 | 44.399 | / |

| MT5 | OXGSXWHJ-MT5-D16-F112-雙60° | 270 | 30 | 16 | 16 | 65 | 35 | 16 | 136 | 72 | 62 | 6.5 | 44.399 | 12 |

B LIGHT HIGH-SPEED FOR SLIM LIVE CENTER

| Morse | Model | L | L1 | L2 | L3 | A | B | b | C | D | E | F | G | K |

| MT3 | QXGSXW-MT3-D10-雙 60° | 186 | 21 | 12 | 15 | 41 | 27 | 10 | 86 | 44 | 56 | 5 | 23.825 | / |

| MT3 | QXGSXWHJ-MT3-D10-F106-雙60° | 186 | 21 | 12 | 15 | 41 | 27 | 10 | 86 | 44 | 56 | 5 | 23.825 | 6 |

| MT4 | QXGSXW-MT4-D12-雙 60° | 225 | 24.5 | 14 | 15 | 47 | 31 | 12 | 109 | 51 | 65 | 6.5 | 31.267 | / |

| MT4 | QXGSXWHJ-MT4-D12-F108-雙 60° | 225 | 24.5 | 14 | 15 | 47 | 31 | 12 | 109 | 51 | 65 | 6.5 | 31.267 | 8 |

| MT5 | QXGSXW-MT5-D16-雙 60° | 280 | 30 | 16 | 16 | 65 | 35 | 16 | 136 | 72 | 72 | 6.5 | 44.399 | / |

| MT5 | QXGSXWHJ-MT5-D16-F112-雙60° | 280 | 30 | 16 | 16 | 65 | 35 | 16 | 136 | 72 | 72 | 6.5 | 44.399 | 12 |

C LIGHT HIGH-SPEED FOR SLIM LIVE CENTER

Features:

The center incorporates needle roller bearings, thrust ball bearings, and a miniature deep groove ball bearing for enhanced performance and durability.

It is suitable for medium-load, medium-high-speed precision processing on CNC lathes.

The extended mandrel improves cutting performance and reduces vibration effectively.

Made from alloy steel, the center is heat-treated to achieve a hardness of HRC 60 ± 2, offering high strength and excellent wear resistance.

The anti-dust cover at the front rotates synchronously with the mandrel, forming a mechanical seal with the main body to effectively resist water and iron chips.

Equipped with needle roller bearings, the center has a compact head design, allowing for wide applications and the ability to bear large loads.

| Morse | Model | L | L1 | L2 | A | B | b | C | D | E | F | G | K |

| MT3 | QXGSXW-MT3-60°-雙尖 | 184 | 46 | 15 | 41 | 27 | 10 | 86 | 44 | 54 | 5 | 23.825 | / |

| MT3 | QXGSXWHJ-MT3-F106-60°-雙尖 | 184 | 46 | 15 | 41 | 27 | 10 | 86 | 44 | 54 | 5 | 23.825 | 6 |

| MT4 | QXGSXW-MT4-60°-雙尖 | 221 | 51 | 15 | 47 | 31 | 12 | 109 | 51 | 61 | 6.5 | 31.267 | / |

| MT4 | QXGSXWHJ-MT4-F108-60°-雙尖 | 221 | 51 | 15 | 47 | 31 | 12 | 109 | 51 | 61 | 6.5 | 31.267 | 8 |

| MT5 | QXGSXW-MT5-60°-雙尖 | 273 | 51 | 16 | 65 | 35 | 16 | 136 | 72 | 65 | 6.5 | 44.399 | / |

| MT5 | QXGSXWHJ-MT5-F112-60°-雙尖 | 273 | 51 | 16 | 65 | 35 | 16 | 136 | 72 | 65 | 6.5 | 44.399 | 12 |

LIGHT HIGH-SPEED LIVE CENTER(CANCHANGE)

Features:

The center integrates needle roller bearings, thrust ball bearings, and a miniature deep groove ball bearing for enhanced performance.

It is suitable for medium-load, medium-high-speed precision processing on CNC lathes.

The extended mandrel effectively improves cutting performance and reduces vibration.

Made from alloy steel, the center is heat-treated to achieve a hardness of HRC 60 ± 2, ensuring high strength and excellent wear resistance.

The anti-dust cover at the front rotates synchronously with the mandrel and forms a mechanical seal with the main body, effectively resisting water and iron chips.

Equipped with needle roller bearings, the center features a compact head design, allowing for a wide range of applications and the ability to bear large loads.

ᅠ

| Morse | Model | L | L1 | A | B | d | C | D | E | F | G |

| MT3 | QXGS-KHS-MT3 | 154 | 10 | 41 | 32 | 12.5 | 86 | 44 | 24 | 5 | 23.825 |

| MT4 | QXGS-KHS-MT4 | 184 | 10 | 47 | 32 | 12.5 | 109 | 51 | 24 | 6.5 | 31.267 |

| MT5 | QXGS-KHS-MT5 | 232 | 10 | 65 | 32 | 12.5 | 136 | 72 | 24 | 6.5 | 44.399 |

A ABROAD LIVE CENTER

Features:

The center incorporates a deep groove ball bearing for reliable performance.

Its compact head design makes it adaptable to various processing demands.

It is suitable for medium-high-speed, light-load processing on specialized lathes.

The head is made from alloy tool steel and heat-treated to achieve a hardness of HRC 60 ± 2, ensuring high strength and excellent wear resistance.

| Morse | Model | L | L1 | C | D | E | A | B | F | G | Accuracy |

| MT1 | WXHZDJ-MT1-D38-60ᄚ-A | 115 | 9 | 57 | 30 | 28 | 38 | 22 | 3.5 | 12.065 | 0.005 |

| MT2 | WXHZDJ-MT2-D48-60ᄚ-A | 143 | 10 | 69 | 38 | 36 | 48 | 30 | 5 | 17.780 | 0.005 |

| MT3 | WXHZDJ-MT3-D53-60ᄚ-A | 169 | 10 | 86 | 44 | 39 | 53 | 34 | 5 | 23.825 | 0.005 |

| MT4 | WXHZDJ-MT4-D58-60ᄚ-A | 202 | 12 | 109 | 46 | 47 | 58 | 40 | 6.5 | 31.267 | 0.005 |

| MT5 | WXHZDJ-MT5-D68-60ᄚ-A | 245 | 15 | 136 | 55 | 54 | 68 | 45 | 6.5 | 44.399 | 0.005 |

B ABROAD LIVE CENTER

Features:

The center utilizes a double-row deep groove ball bearing for enhanced stability and performance.

Its compact head design allows for versatility in meeting various processing demands.

It is suitable for medium-high-speed, light-load processing on specialized lathes.

The head is made from alloy tool steel and heat-treated to a hardness of HRC 60 ᄆ 2, ensuring excellent strength and wear resistance.

| Morse | Model | L | L1 | L2 | C | D | E | B | K | A | F | G | Accuracy |

| MT2 | WXHZDJ-MT2-D63-60°-B | 184 | 115 | 14 | 69 | 47 | 68 | 20 | 31 | 63 | 5 | 17.780 | 0.005 |

| MT2 | WXHZDJ-MT2-D83-60°-B | 211 | 142 | 15 | 69 | 55 | 87 | 30 | 41 | 83 | 5 | 17.780 | 0.005 |

| MT3 | WXHZDJ-MT3-D63-60°-B | 201 | 115 | 14 | 86 | 47 | 68 | 20 | 31 | 63 | 5 | 23.825 | 0.005 |

| MT3 | WXHZDJ-MT3-D83-60°-B | 228 | 142 | 15 | 86 | 55 | 87 | 30 | 41 | 83 | 5 | 23.825 | 0.005 |

| MT4 | WXHZDJ-MT4-D63-60°-B | 224 | 115 | 14 | 109 | 47 | 68 | 20 | 31 | 63 | 6.5 | 31.267 | 0.005 |

| MT4 | WXHZDJ-MT4-D83-60°-B | 251 | 142 | 15 | 109 | 55 | 87 | 30 | 41 | 83 | 6.5 | 31.267 | 0.005 |

| MT5 | WXHZDJ-MT5-D63-60°-B | 251 | 115 | 14 | 136 | 47 | 68 | 20 | 31 | 63 | 6.5 | 44.399 | 0.005 |

| MT5 | WXHZDJ-MT5-D83-60°-B | 278 | 142 | 15 | 136 | 55 | 87 | 30 | 41 | 83 | 6.5 | 44.399 | 0.005 |

C ABROAD LIVE CENTER

Features:

The center utilizes a double-row deep groove ball bearing for enhanced stability and precision.

Its compact head design is adaptable to various processing demands.

It is suitable for medium-high-speed, light-load processing on specialized lathes.

The head is made from alloy tool steel, heat-treated to achieve a hardness of HRC 60 ± 2, providing high strength and excellent wear resistance.

| Morse | Model | L | C | D | E | B | A | F | G | Accuracy |

| MT2 | WXHZDJ-MT2-D63-60°-C | 171 | 69 | 47 | 55 | 102 | 63 | 5 | 17.780 | 0.005 |

| MT2 | WXHZDJ-MT2-D83-60°-C | 196 | 69 | 55 | 72 | 127 | 83 | 5 | 17.780 | 0.005 |

| MT3 | WXHZDJ-MT3-D63-60°-C | 188 | 86 | 47 | 55 | 102 | 63 | 5 | 23.825 | 0.005 |

| MT3 | WXHZDJ-MT3-D83-60°-C | 213 | 86 | 55 | 72 | 127 | 83 | 5 | 23.825 | 0.005 |

| MT4 | WXHZDJ-MT4-D63-60°-C | 211 | 109 | 47 | 55 | 102 | 63 | 6.5 | 31.267 | 0.005 |

| MT4 | WXHZDJ-MT4-D83-60°-C | 236 | 109 | 55 | 72 | 127 | 83 | 6.5 | 31.267 | 0.005 |

| MT5 | WXHZDJ-MT5-D63-60°-C | 238 | 136 | 47 | 55 | 102 | 63 | 6.5 | 44.399 | 0.005 |

| MT5 | WXHZDJ-MT5-D83-60°-C | 263 | 136 | 55 | 72 | 127 | 83 | 6.5 | 44.399 | 0.005 |

HEAVY-LOAD TYPE LIVE CENTER

Features:

Precision ball bearings are used to effectively maintain radial runout, while cylindrical roller bearings increase radial load capacity, and thrust ball bearings handle axial loads.

The mandrel is lengthened at the base, improving cutting performance, reducing vibration, and maintaining accuracy.

Made from GCr15 bearing steel, the mandrel is heat-treated to a hardness of HRC 60 ± 2, ensuring high rigidity and excellent wear resistance.

The front-end gland features a sealing device that prevents cutting fluid and dust from entering the bearing, prolonging the service life of the center.

| Taper shank type | Model | Maximum load T | L | L1 | C | D | B | A | E | G | Limit speed | Accuracy | |

| MT4 | ZX-MT4-0.5T-60° | ≤0.5T | 229 | 12 | 108 | 72 | 35 | 78 | 42.9 | 31.267 | 2500 | 0.01 | |

| MT5 | ZX-MT5-1T-60° | ≤1.0T | 266.2 | 12 | 146 | 75 | 38 | 93.5 | 45.2 | 44.399 | 2000 | 0.01 | |

| MT5 | ZX-MT5-3T-60° | ≤3.0T | 330 | 12 | 146 | 122 | 57.6 | 117 | 62 | 44.399 | 1500 | 0.01 | |

| MT5 | ZX-MT5-5T-60° | ≤5T | 351 | 12 | 146 | 135 | 67.1 | 137 | 70 | 44.399 | 1300 | 0.01 | |

| MT6 | ZX-MT6-4T-60° | ≤4.0T | 383 | 12 | 199 | 122 | 57.6 | 127 | 62 | 63.348 | 1500 | 0.01 | |

| MT6 | ZX-MT6-6T-60° | ≤6.0T | 404 | 12 | 199 | 135 | 67.1 | 137 | 70 | 63.348 | 1400 | 0.01 | |

| MT6 | ZX-MT6-10T-60° | ≤10T | 431 | 12 | 199 | 158 | 71.3 | 157 | 74 | 63.348 | 1200 | 0.01 | |

| MT6 | ZX-MT6-15T-60° | ≤15T | 445 | 12 | 199 | 166 | 78 | 177 | 80 | 63.348 | 1000 | 0.01 | |

| 公制80 | ZX-公制 80-10T-60° | ≤10T | 446 | 12 | 214 | 158 | 71.3 | 157 | 74 | 80 | 1200 | 0.01 | |

| 公制80 | ZX-公制 80-15T-60° | ≤15T | 460 | 12 | 214 | 166 | 78 | 177 | 80 | 80 | 1000 | 0.01 | |

| 公制80 | ZX-公制 80-20T-60° | ≤20T | 441 | 12 | 214 | 144 | 78 | 197 | 83 | 80 | 800 | 0.01 | |

| 公制100 | ZX-公制 100-15T-60° | ≤15T | 475 | 12 | 245 | 140 | 78 | 177 | 80 | 100 | 1000 | 0.01 | |

| 公制100 | ZX-公制 100-20T-60° | ≤20T | 482 | 12 | 245 | 144 | 78 | 197 | 83 | 100 | 800 | 0.01 | |

PRECISION HEAVY LIVE CENTER

Features:

The center integrates heavy-load precise angular contact bearings, tapered roller bearings, and needle roller bearings for optimal performance under heavy loads.

It is suitable for medium-speed, precision processing of heavy loads on CNC lathes.

The extended mandrel enhances cutting performance and reduces vibration.

Constructed from alloy tool steel, the center is heat-treated to achieve a hardness of HRC 60 ± 2, providing high strength and wear resistance.

An oil-adding hole at the head allows for internal bearing lubrication, extending the service life of the center.

The bearing clearance can be adjusted and locked via the front cover to optimize performance.

The front anti-dust seal prevents cutting fluid and dust from entering the bearings, further prolonging the service life.

| Morse | Model | L | L1 | A | B | C | D | E | F | G |

| MT3 | JMZX-MT3-60° | 172 | 15 | 58 | 27 | 86 | 48 | 38 | 5 | 23.825 |

| MT3 | JMZXHJ-MT3-F112-60° | 172 | 15 | 58 | 27 | 86 | 48 | 38 | 5 | 23.825 |

| MT4 | JMZX-MT4-60° | 201 | 15 | 68 | 31 | 109 | 50 | 42 | 6.5 | 31.267 |

| MT4 | JMZXHJ-MT4-F115-60° | 201 | 15 | 68 | 31 | 109 | 50 | 42 | 6.5 | 31.267 |

| MT5 | JMZX-MT5-60° | 242 | 16 | 88 | 35 | 136 | 60 | 46 | 6.5 | 44.399 |

| MT5 | JMZXHJ-MT5-F118-60° | 242 | 16 | 88 | 35 | 136 | 60 | 46 | 6.5 | 44.399 |

| MT6 | JMZX-MT6-60° | 365 | 22 | 138 | 67 | 190 | 95 | 80 | 8 | 63.348 |

| MY6 | JMZXHJ-MT6-F124-60° | 365 | 22 | 138 | 67 | 190 | 95 | 80 | 8 | 63.348 |

ADJUSTMENT TYPE LIVECENTER

Features:

- The shaft is made of alloy steel, hardened through vacuum heat treatment to a hardness of HRC 60° ± 1°.

- The center incorporates a combination of taper roller bearings, thrust bearings, and needle bearings.

- Suitable for medium to heavy loads.

- The center can be adjusted to restore its original load capacity after prolonged use.

- Long-nose live centers are ideal for small workpieces.

- Waterproof design.

| Morse | Model | L | L1 | A | B | C | D | E | F | G |

| MT4 | KT-MT4-60° | 188.5 | 14 | 63 | 26 | 110 | 42 | 36.5 | 6.5 | 31.267 |

| MT5 | KT-MT5-60° | 239.3 | 17 | 79.5 | 35 | 139 | 53 | 47.3 | 6.5 | 44.399 |

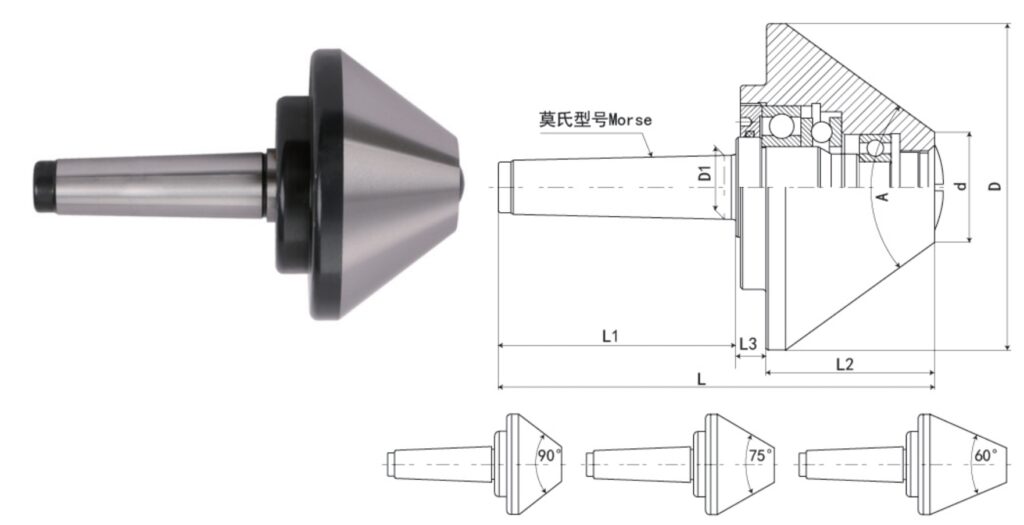

BULL NOSE CENTER TYPE LIVE CENTER

Features:

- The center utilizes a combination of deep groove ball bearings and ball thrust bearings.

- Suitable for medium-speed, precision machining of medium-load CNC lathes.

- The special umbrella-shaped structure at the head is ideal for processing workpieces with central holes and pipes.

- The head is made of alloy tool steel, with a hardness of HRC 60° ± 2° after heat treatment, providing excellent steel performance and high wear resistance.

- This center is intended for lathe processing only. For cylindrical grinders, a high-precision bull-nose live center should be custom ordered.

| Morse | Model | D | D1 | d | L | L1 | L2 | L3 | Accuracy | θ |

| MT2-D63-d20-60° | φ63 | 63 | 17.78 | 20 | 146 | 68 | 68 | 10 | 0.01 | 60° |

| MT2-D83-d25-60° | φ83 | 83 | 17.78 | 25 | 141 | 68 | 61 | 12 | 0.01 | 60° |

| MT2-D103-d25-60° | φ103 | 103 | 17.78 | 25 | 146 | 68 | 61 | 12 | 0.01 | 60° |

| MT2-D103-d30-75° | φ103 | 103 | 17.78 | 30 | 141 | 68 | 57 | 16 | 0.01 | 75° |

| MT3-D63-d20-60° | φ63 | 63 | 23.825 | 20 | 163 | 85 | 68 | 10 | 0.01 | 60° |

| MT3-D83-d25-60° | φ83 | 83 | 23.825 | 25 | 158 | 85 | 61 | 12 | 0.01 | 60° |

| MT3-D103-d25-60° | φ103 | 103 | 23.825 | 25 | 158 | 85 | 57 | 16 | 0.01 | 60° |

| MT3-D103-d30-75° | φ103 | 103 | 23.825 | 30 | 164 | 85 | 63 | 16 | 0.01 | 75° |

| MT3-D118-d40-75° | φ118 | 118 | 23.825 | 40 | 164 | 85 | 63 | 16 | 0.01 | 75° |

| Morse | Model | D | D1 | d | L | L1 | L2 | L3 | Accuracy | θ |

| MT4-D63-d20-60° | φ 63 | 63 | 31.267 | 20 | 186 | 108 | 68 | 10 | 0.01 | 60° |

| MT4-D83-d25-60° | φ83 | 83 | 31.267 | 25 | 181 | 108 | 61 | 12 | 0.01 | 60° |

| MT4-D103-d25-60° | φ103 | 103 | 31.267 | 25 | 187 | 108 | 57 | 16 | 0.01 | 60° |

| MT4-D103-d30-75° | φ103 | 103 | 31.267 | 30 | 181 | 108 | 57 | 16 | 0.01 | 75° |

| MT4-D118-d40-75° | φ118 | 118 | 31.267 | 40 | 187 | 108 | 63 | 16 | 0.01 | 75° |

| MT4-D128-d44-75° | φ128 | 128 | 31.267 | 44 | 191 | 108 | 67 | 16 | 0.01 | 75° |

| MT4-D148-d35-75° | φ 148 | 148 | 31.267 | 35 | 198 | 108 | 80 | 10 | 0.01 | 75° |

| MT4-D158-d45-75° | φ 158 | 158 | 31.267 | 45 | 196 | 108 | 78 | 10 | 0.01 | 75° |

| MT4-D178-d45-75° | φ 178 | 178 | 31.267 | 45 | 210 | 108 | 92 | 10 | 0.01 | 75° |

| MT4-D198-d65-75° | φ 198 | 198 | 31.267 | 65 | 220 | 108 | 102 | 10 | 0.01 | 75° |

| MT4-D248-d105-75° | φ248 | 248 | 31.267 | 105 | 225 | 108 | 107 | 10 | 0.01 | 75° |

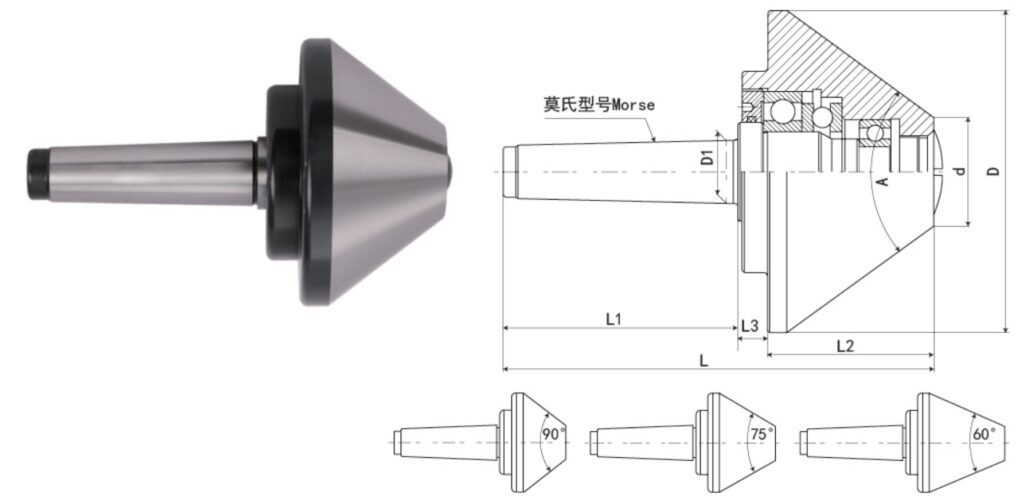

BULL NOSE CENTER TYPE LIVE CENTER

Features:

- The center uses a combination of deep groove ball bearings and ball thrust bearings.

- Suitable for medium-speed, precise processing of medium-load workpieces on CNC lathes.

- The special umbrella-shaped structure at the head is designed for processing workpieces with central holes and pipes.

- The head is made of alloy tool steel, with a hardness of HRC 60° ± 2° after heat treatment, ensuring high steel performance and wear resistance.

- This center is intended solely for lathe processing. For use with cylindrical grinders, a high-precision bull-nose live center should be custom ordered.

| Morse | Model | D | D1 | d | L | L1 | L2 | L3 | Accuracy | θ |

| MT5-D63-d20-60° | φ63 | 63 | 44.399 | 20 | 214 | 136 | 68 | 10 | 0.01 | 60° |

| MT5-D83-d25-60° | φ 83 | 83 | 44.399 | 25 | 209 | 136 | 61 | 12 | 0.01 | 60° |

| MT5-D103-d30-60° | φ 103 | 103 | 44.399 | 30 | 209 | 136 | 57 | 16 | 0.01 | 60° |

| MT5-D103-d30-75° | φ 103 | 103 | 44.399 | 30 | 209 | 136 | 57 | 16 | 0.01 | 75° |

| MT5-D118-d40-75° | φ 118 | 118 | 44.399 | 40 | 215 | 136 | 63 | 16 | 0.01 | 75° |

| MT5-D128-d44-75° | φ 128 | 128 | 44.399 | 44 | 219 | 136 | 67 | 16 | 0.01 | 75° |

| MT5-D148-d35-75° | φ 148 | 148 | 44.399 | 35 | 226 | 136 | 80 | 10 | 0.01 | 75° |

| MT5-D158-d45-75° | φ 158 | 158 | 44.399 | 45 | 224 | 136 | 78 | 10 | 0.01 | 75° |

| MT5-D178-d45-75° | φ178 | 178 | 44.399 | 45 | 238 | 136 | 92 | 10 | 0.01 | 75° |

| MT5-D198-d65-75° | φ 198 | 198 | 44.399 | 65 | 248 | 136 | 102 | 10 | 0.01 | 75° |

| MT5-D248-d105-75° | φ248 | 248 | 44.399 | 105 | 253 | 136 | 107 | 10 | 0.01 | 75° |

| MT5-D300-d140-75° | φ300 | 300 | 44.399 | 140 | 266 | 136 | 120 | 10 | 0.01 | 75° |

| MT5-D320-d155-75° | φ320 | 320 | 44.399 | 155 | 271 | 136 | 125 | 10 | 0.01 | 75° |

| MT5-D350-d170-75° | φ350 | 350 | 44.399 | 170 | 281 | 136 | 135 | 10 | 0.01 | 75° |

| MT5-D410-d200-75° | φ410 | 410 | 44.399 | 200 | 311 | 136 | 160 | 15 | 0.01 | 75° |

| Morse | Model | D | D1 | d | L | L1 | L2 | L3 | Accuracy | θ |

| MT6-D118-d40-75° | φ118 | 118 | 63.348 | 40 | 268 | 189 | 63 | 16 | 0.01 | 75° |

| MT6-D128-d44-75° | φ128 | 128 | 63.348 | 44 | 272 | 189 | 67 | 16 | 0.01 | 75° |

| MT6-D148-d35-75° | φ 148 | 148 | 63.348 | 35 | 279 | 189 | 80 | 10 | 0.01 | 75° |

| MT6-D158-d45-75° | φ 158 | 158 | 63.348 | 45 | 277 | 189 | 78 | 10 | 0.01 | 75° |

| MT6-D178-d45-75° | φ 178 | 178 | 63.348 | 45 | 291 | 189 | 92 | 10 | 0.01 | 75° |

| MT6-D198-d65-75° | φ 198 | 198 | 63.348 | 65 | 301 | 189 | 102 | 10 | 0.01 | 75° |

| MT6-D248-d105-75° | φ248 | 248 | 63.348 | 105 | 306 | 189 | 107 | 10 | 0.01 | 75° |

| MT6-D300-d140-75° | φ 300 | 300 | 63.348 | 140 | 319 | 189 | 120 | 10 | 0.01 | 75° |

| MT6-D320-d155-75° | φ 320 | 320 | 63.348 | 155 | 324 | 189 | 125 | 10 | 0.01 | 75° |

| MT6-D350-d170-75° | φ 350 | 350 | 63.348 | 170 | 334 | 189 | 135 | 10 | 0.01 | 75° |

| MT6-D410-d200-75° | φ 410 | 410 | 63.348 | 200 | 365 | 189 | 160 | 15 | 0.01 | 75° |

GRINDING MACHINE HIGH-PRECISION BULL NOSE CENTER TYPE LIVE CENTER

Features:

- The umbrella-shaped structure at the head is designed for processing workpieces with central holes and pipes.

- The head is made from alloy tool steel, with a hardness of HRC 60° ± 2° after heat treatment, ensuring high steel performance and excellent wear resistance.

| Morse | Model | G | L | L1 | L2 | L3 | L4 | L5 | D | D1 | a | d | Accuracy |

| MT3 | GJDSXDJ-MT3-D63-d25-60° | 23.825 | 167.5 | 90.5 | 77 | 33 | – | – | 63 | – | 5 | 25 | 0.003 |

| MT3 | GJDSXDJ-MT3-D83-d40-60° | 23.825 | 165.6 | 90.6 | 75 | 37 | 19.5 | 18.5 | 83 | 70 | 5 | 40 | 0.003 |

| MT3 | GJDSXDJ-MT3-D103-d60-60° | 23.825 | 165.6 | 90.6 | 75 | 37 | 9.5 | 28.5 | 103 | 70 | 5 | 60 | 0.003 |

| MT4 | GJDSXDJ-MT4-D63-d25-60° | 31.267 | 190.5 | 113.5 | 77 | 33 | – | – | 63 | – | 6.5 | 25 | 0.003 |

| MT4 | GJDSXDJ-MT4-D83-d40-60° | 31.267 | 188.6 | 113.6 | 75 | 37 | 19.5 | 18.5 | 83 | 70 | 6.5 | 40 | 0.003 |

| MT4 | GJDSXDJ-MT4-D103-d60-60° | 31.267 | 188.6 | 113.6 | 75 | 37 | 9.5 | 28.5 | 103 | 70 | 6.5 | 60 | 0.003 |

| MT4 | GJDSXDJ-MT4-D118-d70-60° | 31.267 | 222.4 | 114.4 | 108 | 42 | 15 | 51 | 118 | 100 | 6.5 | 70 | 0.003 |

| MT4 | GJDSXDJ-MT4-D128-d80-60° | 31.267 | 222.4 | 114.4 | 108 | 42 | 15 | 51 | 128 | 105 | 6.5 | 80 | 0.003 |

| MT5 | GJDSXDJ-MT5-D63-d25-60° | 44.399 | 217.5 | 140.5 | 77 | 33 | – | – | 63 | – | 6.5 | 25 | 0.003 |

| MT5 | GJDSXDJ-MT5-D83-d40-60° | 44.399 | 215.6 | 140.6 | 75 | 37 | 19.5 | 18.5 | 83 | 70 | 6.5 | 40 | 0.003 |

| MT5 | GJDSXDJ-MT5-D103-d60-60° | 44.399 | 215.6 | 140.6 | 75 | 37 | 9.5 | 28.5 | 103 | 70 | 6.5 | 60 | 0.003 |

| MT5 | GJDSXDJ-MT5-D118-d70-60° | 44.399 | 249.4 | 141.4 | 108 | 42 | 15 | 51 | 118 | 100 | 6.5 | 70 | 0.003 |

| MT5 | GJDSXDJ-MT5-D128-d80-60° | 44.399 | 249.4 | 141.4 | 108 | 42 | 15 | 51 | 128 | 105 | 6.5 | 80 | 0.003 |

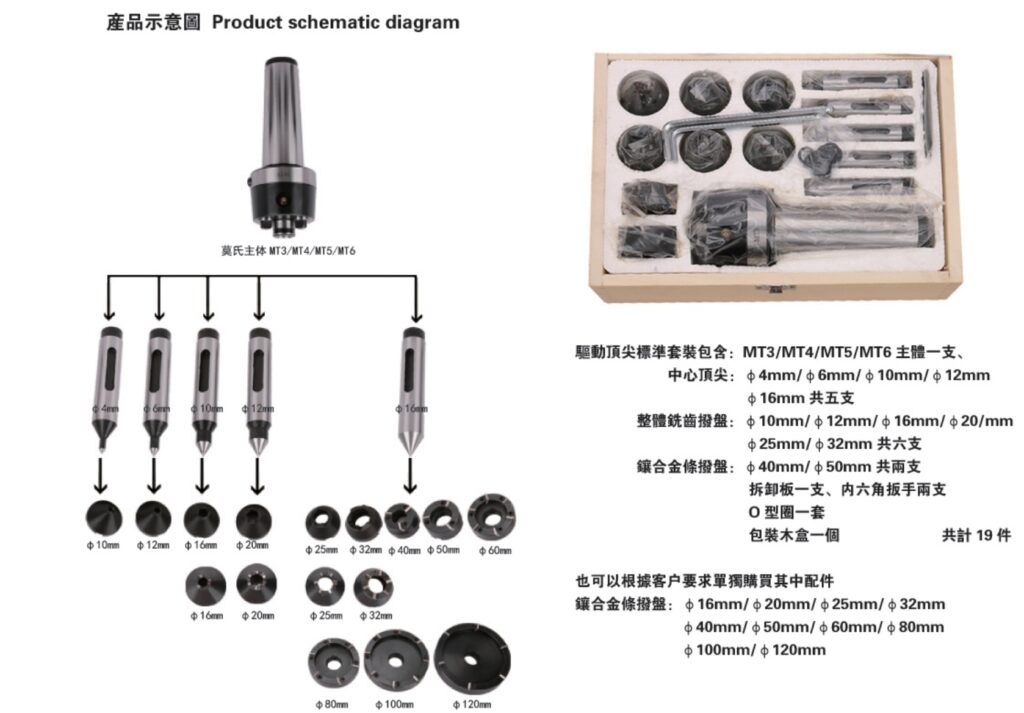

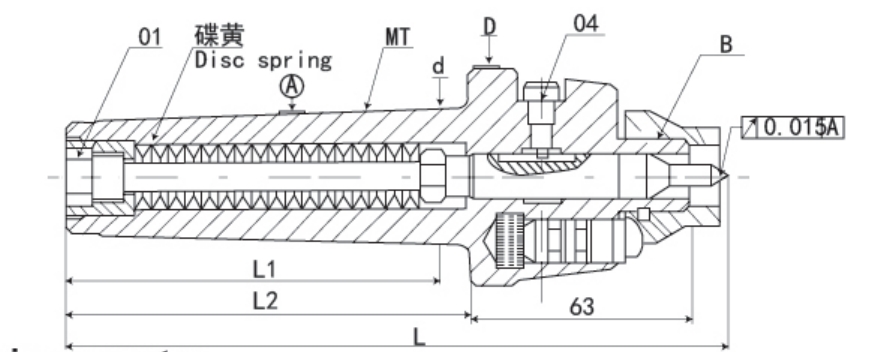

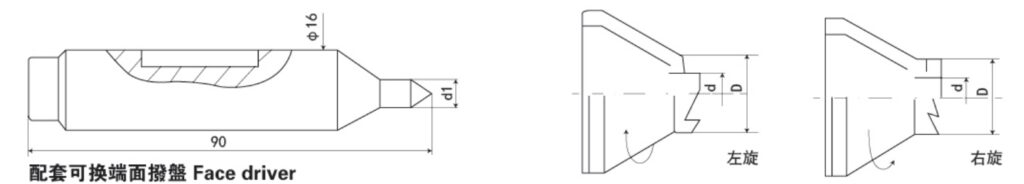

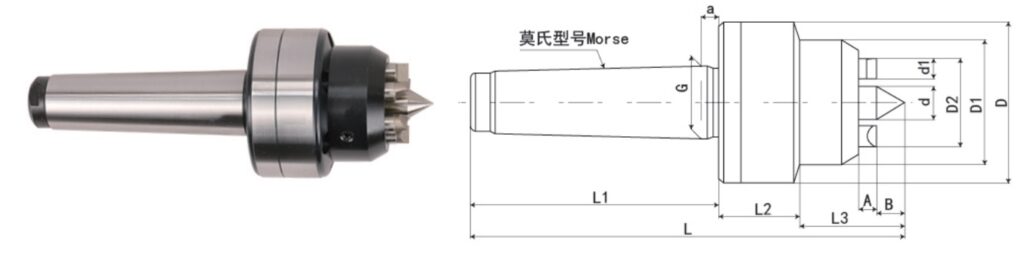

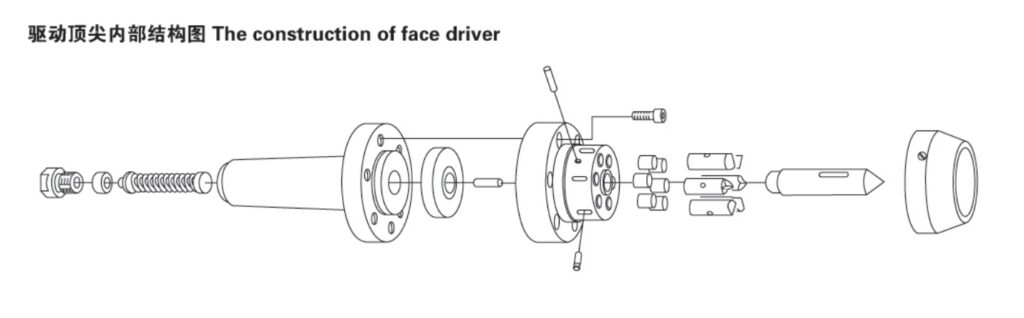

CONSTANT HYDROSTARTER FACE DRIVER

Product Information:

The constant hydrostarter face driver is primarily used on forming lathes, CNC lathes, and standard lathes to process axis-type workpieces. With just one collet, you can complete all exterior dimensions of the workpiece. By using the workpiece’s center hole for positioning, high-quality results can be ensured.

The driver plate is propelled by three floating hydraulic cylinders, pressing firmly against the end of the workpiece to rotate it. Even if the end face and the axis are misaligned by up to 5 degrees, the constant face driver will still function normally.

The constant face driver is typically provided with the driving center body, along with interchangeable centers and driver plates. Please specify your requirements when placing an individual order. Additionally, we can manufacture custom interchangeable centers and driver plates upon request.

| Model | MT | Cutting range | L | L1 | d | D | Center top | Dial | KG | Remarks |

| D233 | MT3 | 11-80mm | 152 | 82 | 23.825 | 70 | 4 6 10 12 16 | 10 12 16 20 25 32 40 50 | 40 | 左旋(L) |

| D233R | MT3 | 11-80mm | 152 | 82 | 23.825 | 70 | 40 | 右旋(R) | ||

| D234 | MT4 | 11-80mm | 166 | 97.7 | 31.267 | 70 | 60 | 左旋(L) | ||

| D234R | MT4 | 11-80mm | 166 | 97.7 | 31.267 | 70 | 60 | 右旋(R) | ||

| D235 | MT5 | 11-80mm | 193 | 123.7 | 44.399 | 70 | 80 | 左旋(L) | ||

| D235R | MT5 | 11-80mm | 193 | 123.7 | 44.399 | 70 | 80 | 右旋(R) | ||

| D236 | MT6 | 17-160mm | 246 | 178 | 63.348 | 70 | 120 | 左旋(L) | ||

| D236R | MT6 | 17-160mm | 246 | 178 | 63.348 | 70 | 120 | 右旋(R) |

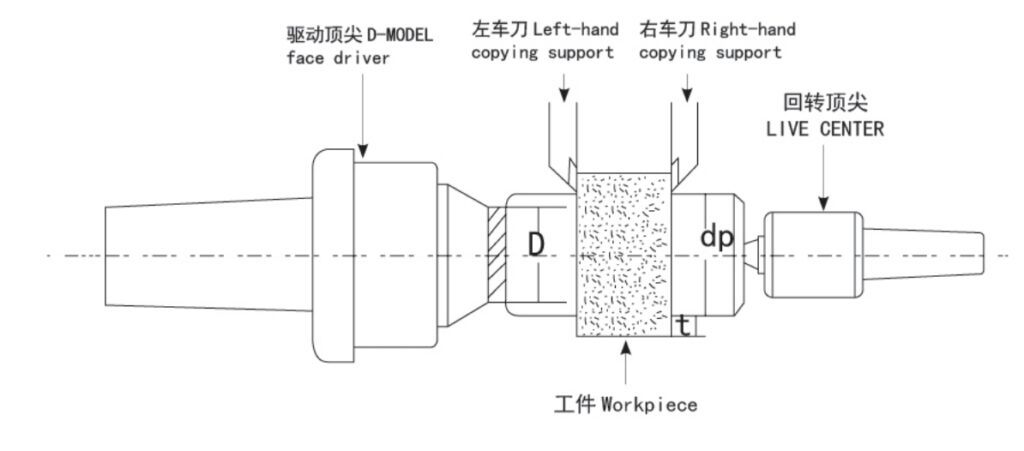

Mounting Instructions:

Selecting Components

Choose the appropriate center and driver plate based on the diameter of the workpiece.Changing the Center

- Loosen the bolt to remove the old center.

- Insert the new center, ensuring that the bolt’s guide part aligns with the leading groove.

- Tighten the bolt. The center should now be able to move along the axis but remain non-rotational.

Changing the Driver Plate

- Insert the driver plate into the body (B), making sure the plate’s groove aligns with the thinner section of the piston.

- Gently lever the driver plate into place.

Adjusting the Center Length

- Use Piston 1 to adjust the length of the center.

- Ensure there is a gap of 3-7 mm between the center and the gear on the driver plate for optimal performance.

Fixing the Workpiece

Secure one side of the center hole on the active center.

Support the other side using the apex of the lathe.

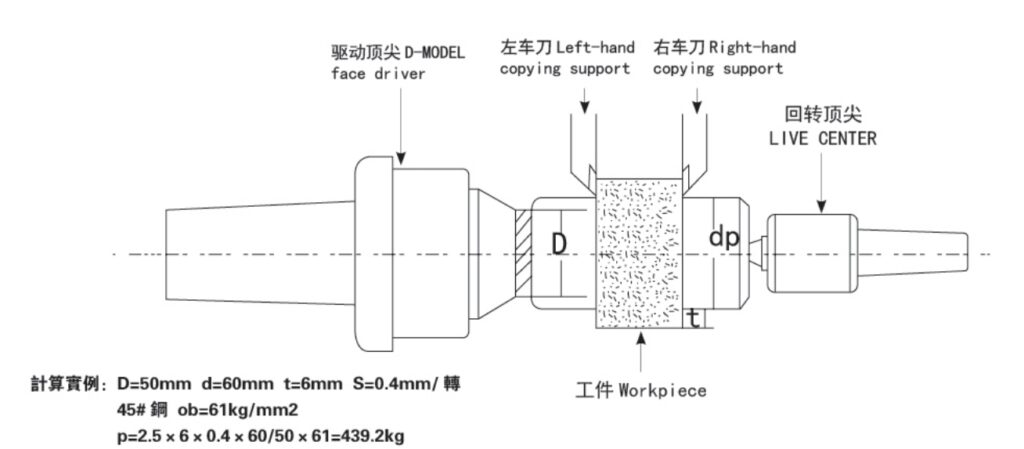

The power of the strut can be calculated with the following formula:

p=2.5ts⋅ob⋅ip = 2.5ts \cdot ob \cdot ip=2.5ts⋅ob⋅i

Where:

- p = Power of the strut

- t = Cutting depth (mm)

- s = Rotational speed (revolutions per minute)

- ob = Tensile strength of the material

- i = Ratio derived from the workpiece dimensions (d/D as indicated in Figure 2)

Maintenance:

Lubrication

Ensure that there is sufficient 20# engine oil to lubricate the active center. Tighten the necessary components as needed.Hydraulic Pressure Maintenance

If hydraulic pressure is low, follow these steps:- Loosen the two screw caps on the seal.

- Add an appropriate amount of hyperbolic gear oil until the piston’s surface aligns with the main body.

- Tighten the sealing body bolts.

- If the washer in the sealing assembly is damaged, replace it immediately. The seal was pre-assembled at the factory, and normally, it should not be removed.

Recommended Cutting Range

- Maximum cutting depth: t = 5 mm

- Maximum cutting speed: s = 0.4 mm/turn

Easily Damaged Parts

- O-type Seal Ring: φ 16*2.4

- Combination Washer: Type B6

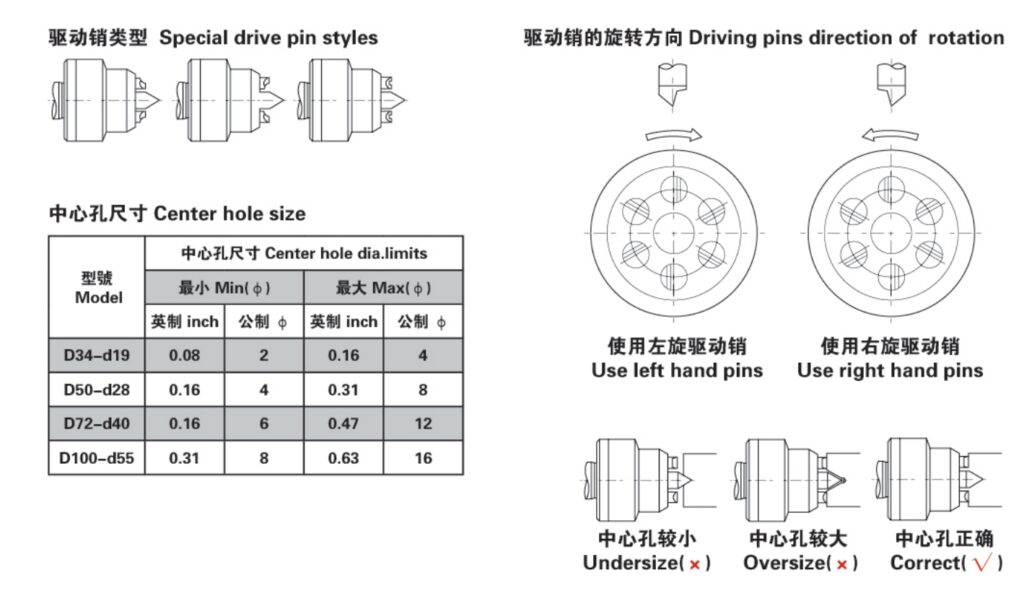

MECHANICAL DRIVE CENTER

| Model | MT | D | D1 | L1 | L2 | L3 | a | A | B | L | D2 | d | d1 | driving pins | Work size | Weight |

| JXQD-MT3-D34-d19 | MT3 | 42 | 30 | 89 | 24.5 | 29.5 | 6 | 5 | 4.3 | 143 | 17 | 5 | 5 | 4 | φ 19-φ 34 | 50 |

| JXQD-MT4-D34-d19 | MT4 | 42 | 30 | 108 | 24.5 | 29.5 | 8 | 5 | 4.3 | 163 | 17 | 5 | 5 | 4 | φ 19-φ 34 | 50 |

| JXQD-MT5-D34-d19 | MT5 | 42 | 30 | 136 | 24.5 | 29.5 | 8 | 5 | 4.3 | 191 | 17 | 5 | 5 | 4 | φ 19-φ 34 | 50 |

| JXQD-MT3-D50-d28 | MT3 | 52 | 40 | 89 | 26.5 | 35.8 | 6 | 6.5 | 7.8 | 150.3 | 26 | 9 | 7 | 5 | φ 28-φ 50 | 55 |

| JXQD-MT4-D50-d28 | MT4 | 52 | 40 | 108 | 26.5 | 35.8 | 8 | 6.5 | 7.8 | 170.3 | 26 | 9 | 7 | 5 | φ 28-φ 50 | 55 |

| JXQD-MT5-D50-d28 | MT5 | 52 | 40 | 136 | 26.5 | 35.8 | 8 | 6.5 | 7.8 | 198.3 | 26 | 9 | 7 | 5 | φ 28-φ 50 | 55 |

| JXQD-MT3-D72-d40 | MT3 | 70 | 54 | 89 | 36 | 45 | 6 | 9 | 11 | 170 | 38 | 14 | 9 | 6 | φ 40-φ 72 | 65 |

| JXQD-MT4-D72-d40 | MT4 | 70 | 54 | 108 | 36 | 45 | 8 | 9 | 11 | 189 | 38 | 14 | 9 | 6 | φ 40-φ 72 | 65 |

| JXQD-MT5-D72-d40 | MT5 | 70 | 54 | 136 | 36 | 45 | 8 | 9 | 11 | 217 | 38 | 14 | 9 | 6 | φ 40-φ 72 | 65 |

| JXQD-MT4-D100-d55 | MT4 | 82 | 72 | 108 | 40 | 56.1 | 8 | 11 | 14.1 | 204.1 | 54 | 20 | 14 | 6 | φ 55-φ 100 | 100 |

| JXQD-MT5-D100-d55 | MT5 | 82 | 72 | 136 | 40 | 56.1 | 8 | 11 | 14.1 | 232.1 | 54 | 20 | 14 | 6 | φ 55-φ 100 | 100 |

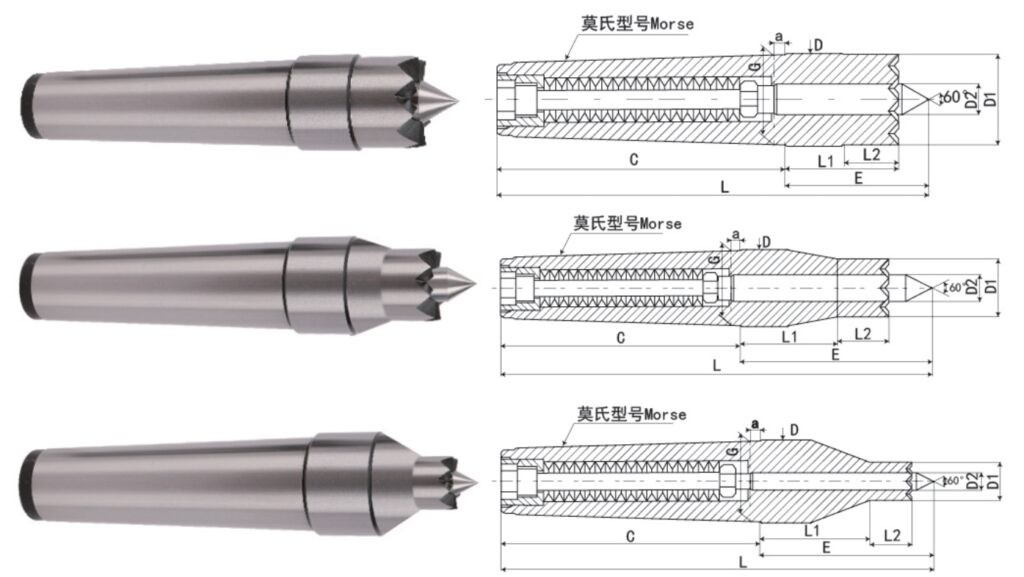

FIXED FACE DRIVER CENTER

Features:

- The body and center shaft are made of alloy steel, treated with both heat and sub-zero processes. Hardness: HRC 60° ± 1°.

- A driving dog is required for traditional lathe operations to prevent the workpiece from stopping. These work-driving centers feature a 6-teeth or 8-teeth design, eliminating the need for traditional driving dogs.

- It supports the workpiece on the end surface, enabling easy setup and rapid machining.

- The work-driving center is also suitable for use on gear hobbing machines.

| Morse | Model | G | L | L1 | L2 | C | E | D | D1 | D2 | a | FIG |

| MT3 | GDQDDJ-MT3-D32 | 23.825 | 146 | 44 | 22 | 86 | 60 | 26 | 32 | 16 | 5 | 1 |

| MT3 | GDQDDJ-MT3-D25 | 23.825 | 143 | 44 | 22 | 86 | 57 | 26 | 25 | 12 | 5 | 1 |

| MT3 | GDQDDJ-MT3-D20 | 23.825 | 143 | 46 | 15 | 86 | 57 | 26 | 20 | 10 | 5 | 2 |

| MT3 | GDQDDJ-MT3-D16 | 23.825 | 141 | 46 | 15 | 86 | 55 | 26 | 16 | 8 | 5 | 2 |

| MT3 | GDQDDJ-MT3-D12 | 23.825 | 139 | 46 | 15 | 86 | 53 | 26 | 12 | 6 | 5 | 3 |

| MT3 | GDQDDJ-MT3-D10 | 23.825 | 139 | 46 | 15 | 86 | 53 | 26 | 10 | 5 | 5 | 3 |

| MT4 | GDQDDJ-MT4-D32 | 31.267 | 169 | 44 | 22 | 109 | 60 | 33 | 32 | 16 | 6.5 | 1 |

| MT4 | GDQDDJ-MT4-D25 | 31.267 | 166 | 44 | 22 | 109 | 57 | 33 | 25 | 12 | 6.5 | 1 |

| MT4 | GDQDDJ-MT4-D20 | 31.267 | 166 | 46 | 15 | 109 | 57 | 33 | 20 | 10 | 6.5 | 2 |

| MT4 | GDQDDJ-MT4-D16 | 31.267 | 164 | 46 | 15 | 109 | 55 | 33 | 16 | 8 | 6.5 | 2 |

| MT4 | GDQDDJ-MT4-D12 | 31.267 | 162 | 46 | 15 | 109 | 53 | 33 | 12 | 6 | 6.5 | 3 |

| MT4 | GDQDDJ-MT4-D10 | 31.267 | 162 | 46 | 15 | 109 | 53 | 33 | 10 | 5 | 6.5 | 3 |